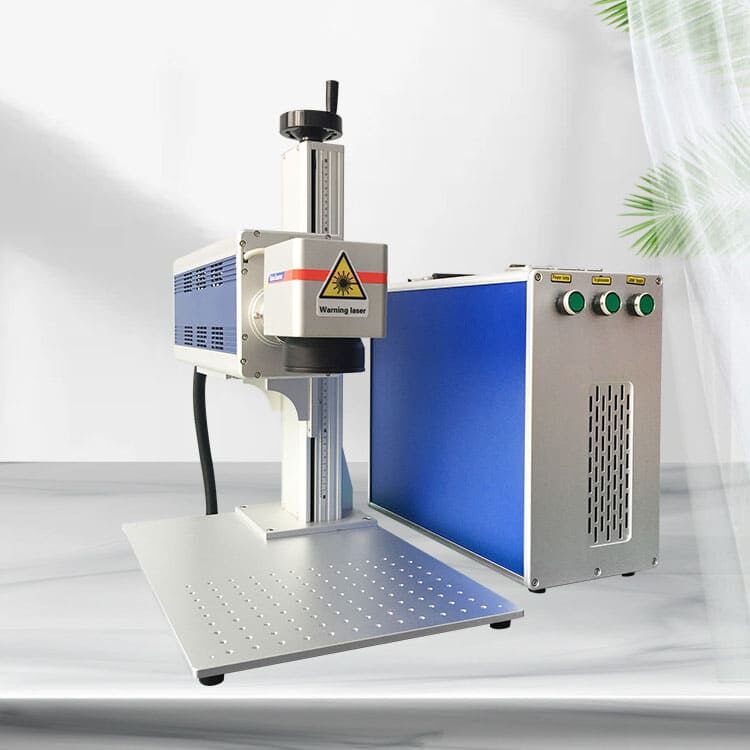

Core Parameter Configuration in CNC Laser Engraving Machines

Power Output Ranges (40W-6000W) and Material Penetration

The depth and efficiency of processing are mainly controlled by laser power. Non-metallic materials such as wood or acrylic are engraved with system output from 40W to 300W with surface depths less than 0.5mm. Lasers for industrial metal work up to 1,000W-6,000W go through up to 12mm in stainless steel (Precision Manufacturing Journal, 2024). Operators walk the line between power and heat sensitivity—too many watts will warp thin aluminum while not enough won’t make a mark on hardened tool steels.

Speed Settings (20-5000mm/s) for Precision Engraving

Traversing speed is inversely related to the resolution of detail and production speed. Fast settings (3,000-5,000mm/s) are perfect for marking Anodized Aluminum at relatively shallow engraving.Micro-engraving on aerospace components when even a slight burr is unacceptable, has been accomplished successfully at 20-150mm/s.A 2023 study of material science showed that at 500mm/s with 80W of power, you dont have to worry about heat distortion on 25μm with titanium alloys. Real-time power ramping returns prevent under-engraved area on a curve surface, and reduces carbon residues on the cutting edge.

Focal Length Adjustment (2.5"-7.5") for Depth Control

Focal length determines the laser’s spot size and energy density distribution. Shorter focal lengths (2.5"-3.5") concentrate energy for <0.1mm beam diameters, ideal for etching fine text on silicon wafers. For deep engraving in layered composites, 7.5" lenses provide consistent 1.2mm penetration with ±0.05mm depth uniformity across 1m² work areas.

Laser Source Types and Material Compatibility

Fiber Lasers vs CO2 Lasers for Metal Engraving

Fiber lasers are most prominent in metal processing due to their 1,060 nm wavelength allowing for excellent absorption in all types of conductivity metals. These systems are capable of high precision engraving on stainless steel and aluminum alloys, up to 7,000 mm/s with remaining side sharpness below 20 μm (CO 2 laser (10600 nm) has poor results without previous metal treatment or secondary patients for bright and dark contrast).

UV Laser Optimization for Delicate Materials

UV lasers (355 nm) enable cold-processing workflows for heat-sensitive substrates like medical-grade silicones and polycarbonates. Their photon energy level (3.5 eV) breaks molecular bonds without thermal distortion, achieving 15 μm resolution in microfluidic device manufacturing. Operators maintain peak performance by implementing hourly beam collimation checks and nitrogen purge systems.

Diode Laser Limitations in Industrial Applications

While diode lasers offer entry-level affordability (5-40W range), their 450-980 nm wavelengths limit material versatility. These systems achieve only 60 dpi resolution on anodized aluminum and fail to mark untreated steels. Industrial users report 70% faster wear rates compared to fiber lasers when processing acrylics beyond 3 mm thickness.

Workflow Integration Parameters

Software Compatibility with CAD/CAM Systems

Contemporary CNC laser engraving machines require tight coupling with CAD/CAM software to translate design files into machine instructions. Systems, which support file formats for universal exchange (e.g. DXF, STEP as intermediate file), result in the export errors being 38 % lower than on the basis of proprietary formats (Machinery Systems Report 2023). The latest generation of workflow integration software allows intelligent data to be taken from 3D models for engraving depth and tool paths.

Ethernet/IP Communication Protocol Requirements

Industrial-grade engraving systems require Ethernet/IP protocols to synchronize with factory automation networks. These protocols enable <25ms latency for real-time parameter adjustments during high-speed jobs – a necessity when engraving aerospace components requiring 5μm precision. Dual-port Gigabit interfaces have become standard for simultaneously handling job transfers and machine status updates.

Automation Configurations for Production Environments

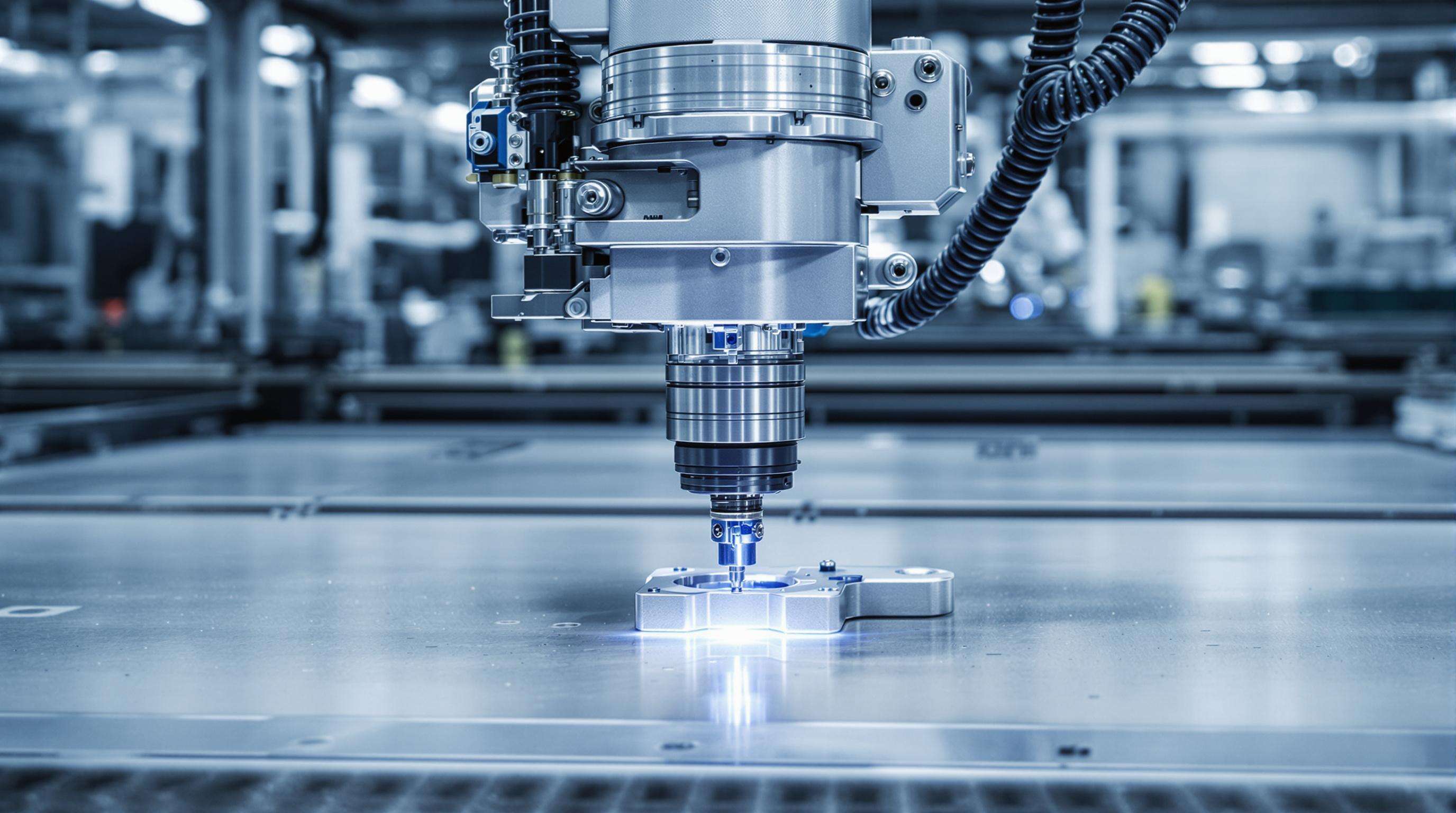

Robotic Arm Integration for Multi-axis Engraving

Modern CNC laser systems achieve ±0.02mm positioning accuracy when paired with industrial robotic arms, enabling precise 5-axis engraving on complex geometries.

| Parameter | Specification Range | Application Impact |

|---|---|---|

| Arm reach distance | 800mm–2000mm | Determines maximum workpiece size |

| Payload capacity | 10kg–50kg | Affects material handling options |

| Repeatability | ±0.05mm–±0.15mm | Influences engraving consistency |

Proper synchronization between robotic motion and laser pulsing prevents thermal distortion, particularly in aluminum (6061-T6) and stainless steel (304L) alloys.

Rotary Attachment Specifications for Cylindrical Objects

Standard rotary units support diameters from Ø10mm to Ø300mm with ‰3μm radial runout error. For bottle engraving applications:

- Rotation speed: 30–300 RPM (directly impacts line spacing)

- Chuck type: 3-jaw vs. collet-based gripping (material-specific selection)

- Torque rating: Minimum 2.5Nm for Ø100mm steel shafts

Quality Control and Calibration Systems

Vision Systems for Engraving Depth Verification

Modern CNC laser engravers integrate vision systems with <2 μm resolution cameras to validate engraving depth in real time. These optical measurement tools compare surface topography against CAD models through AI-powered depth mapping algorithms, automatically adjusting power settings when deviations exceed ±0.05 mm.

Laser Beam Alignment Procedures Every 500 Hours

Consistent beam alignment maintains <0.01° angular accuracy critical for multi-axis engraving systems. Technicians use collimators and beam profilers to:

- Measure M² beam quality factor (target: 1.1-1.3)

- Verify beam circularity (tolerance: ±5% ellipticity)

- Align galvanometer mirrors to 0.001° precision

Post-alignment energy density tests must confirm ‰2% variation across the 400x400mm work

FAQ

What is the difference between fiber lasers and CO2 lasers in CNC laser engraving machines?

Fiber lasers are specifically designed for metal processing due to their 1,060 nm wavelength, which offers excellent absorption in conductive metals, enabling high precision and speed. CO2 lasers, with a wavelength of 10,600 nm, are less effective for metals without pre-treatment.

How does the power output range affect material penetration in CNC laser engraving?

The power output determines how deeply a laser can engrave material. Lower power outputs (40W-300W) are suited for non-metallic materials with surface depths up to 0.5mm, while higher outputs (1,000W-6,000W) can penetrate up to 12mm in metals like stainless steel.

What does Ethernet/IP communication protocols do in engraving machines?

These protocols enable real-time parameter adjustments with minimal latency, a necessity for precision jobs like engraving aerospace components. They facilitate synchronization with factory automation networks and handle simultaneous job transfers and status updates.

Why are vision systems important in CNC laser engraving machines?

Vision systems provide real-time validation of engraving depth by using high-resolution cameras to compare surface topography against CAD models. This ensures accurate engravings and adjusts power settings for deviations beyond acceptable limits.

Table of Contents

- Core Parameter Configuration in CNC Laser Engraving Machines

- Laser Source Types and Material Compatibility

- Workflow Integration Parameters

- Automation Configurations for Production Environments

- Quality Control and Calibration Systems

-

FAQ

- What is the difference between fiber lasers and CO2 lasers in CNC laser engraving machines?

- How does the power output range affect material penetration in CNC laser engraving?

- What does Ethernet/IP communication protocols do in engraving machines?

- Why are vision systems important in CNC laser engraving machines?