CO₂ Lasers: Versatility for Organic Materials

CO₂ laser systems (10.6 micrometers wavelength) excel at engraving wood, leather, acrylic, and glass with minimal contact wear. Their precision makes them ideal for signage, packaging, and decorative crafts, though power calibration is critical to prevent charring on heat-sensitive materials.

Fiber Lasers: Precision on Metals and Alloys

With a 1064-nanometer wavelength, fiber lasers achieve sub-millimeter accuracy on metals like stainless steel and titanium. They minimize heat dispersion—crucial for aerospace and medical device manufacturing—and process metals 30% faster than CO₂ lasers (Laser Materials Institute, 2025).

Diode Lasers: Compact Solutions for Beginners

These affordable 5–20W systems suit hobbyists engraving wood, leather, or coated metals. While ideal for jewelry and awards, their shorter lifespan (8,000–10,000 hours) makes them better for prototyping than high-volume production.

UV Lasers: Micro-Engraving Specialty Applications

UV lasers (355nm) achieve under 10-micron resolution on glass, ceramics, and semiconductors via photochemical reactions. Their heat-free process benefits electronics and medical implants, though operational costs run 40–60% higher than fiber lasers.

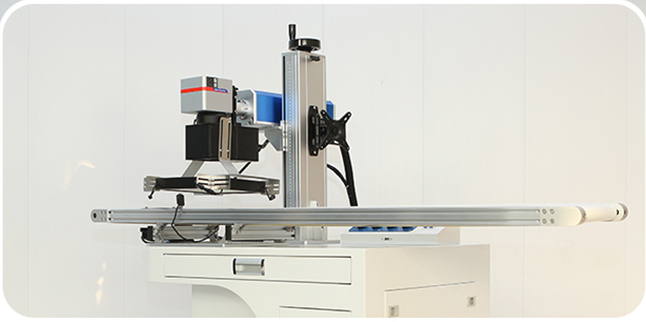

Hybrid Systems: Multi-Material Flexibility

Combining CO₂ and fiber modules, hybrids reduce material changeover time by 65% (LaserTech 2024). They’re costlier but indispensable for workshops handling metals and organics (e.g., automotive parts and plastic trim) in one workflow.

Material Compatibility in Laser Machine Engraving

Metals: From Aluminum to Precious Alloys

Fiber lasers mark stainless steel and titanium via surface melting, while lower settings prevent silver overheating. Copper and brass require specialized configurations to overcome reflectivity.

Plastics: Avoiding Toxic Fumes and Melting

CO₂ lasers at 40–60% power cleanly engrave cast acrylic. Avoid PVC and ABS—their chlorine emissions damage optics. Always ventilate workspaces and verify material certifications.

Wood/Glass/Ceramics: Power Calibration Tips

- Wood: 30W CO₂ lasers for maple (500mm/s); 20% higher for dense hardwoods like oak

- Glass: <50% power with circular motions to prevent cracking

- Ceramics: 2–3 shallow passes at 1000dpi

Power Output and Speed Specifications

Wattage Guidelines for Different Materials

| Material Type | Recommended Wattage | Speed Range (mm/s) |

|---|---|---|

| Stainless Steel (1–3mm) | 1.5 kW | 20–30 |

| Aluminum (1–3mm) | 2 kW | 25–40 |

| ABS Plastic (2–5mm) | 40W | 100–150 |

Balancing Speed and Detail

- High detail: <500mm/s, 600+ DPI

- Production runs: 1000mm/s at 20–30% power

Stability for High-Volume Work

Industrial systems maintain ±2% power consistency with:

- Water chillers (20–25°C)

- Voltage regulators

- Modular optics for quick adjustments

Cost Considerations

Initial vs. Operating Costs

Entry-level systems: $500; industrial models: $20,000+. Budget for:

- Software subscriptions ($50–300/month)

- Material replenishment ($200–1,000/year)

Maintenance and Upgrades

Annual costs: $100–500 for cleaning/calibration. Allocate 15–20% of machine cost yearly for upgrades like rotary attachments ($800–1,200).

ROI for Commercial Use

Price services at $30–50/hour. A $15,000 machine engraving 40 items/day at $5 profit each breaks even in <10 months.

Essential Features

Software Compatibility

Support for SVG/DXF (vector) and BMP/PNG (raster) cuts preprocessing time by 30–50% (Digital Fabrication Journal, 2023).

Automation for Batch Jobs

Rotary axes, barcode scanning, and camera alignment reduce setup time 70% for 500+ item runs.

Cooling Systems

Water-cooled CO₂ lasers double tube lifespan with ±0.5°C stability (Applied Optics Quarterly, 2022).

Buyer's Guide for Beginners

Ease of Use

Pre-configured settings and auto-focus reduce setup time 70%.

Safety

Class 1 certification with:

- Interlocked enclosures

- Fume extraction

- Motion sensors

Support

Prioritize 24/7 support and 2-year warranties covering laser tubes.

Upgradability

Modular designs allow future additions like high-power lenses or air-assist systems.

FAQ

What are the main types of laser engraving systems?

The main types of laser engraving systems include CO₂ lasers, fiber lasers, diode lasers, UV lasers, and hybrid systems. Each type is suited for specific materials and applications.

Which laser system is best for metal engraving?

Fiber lasers are best for metal engraving due to their precision and speed, especially for materials like stainless steel and titanium.

Are CO₂ lasers suitable for engraving on plastic?

CO₂ lasers can engrave certain plastics, such as cast acrylic, but are not suitable for PVC or ABS due to toxic fumes from chlorine emissions.

What factors should be considered for buying a laser machine?

Consider ease of use, safety features, support, upgradability, and initial and operating costs when buying a laser machine.