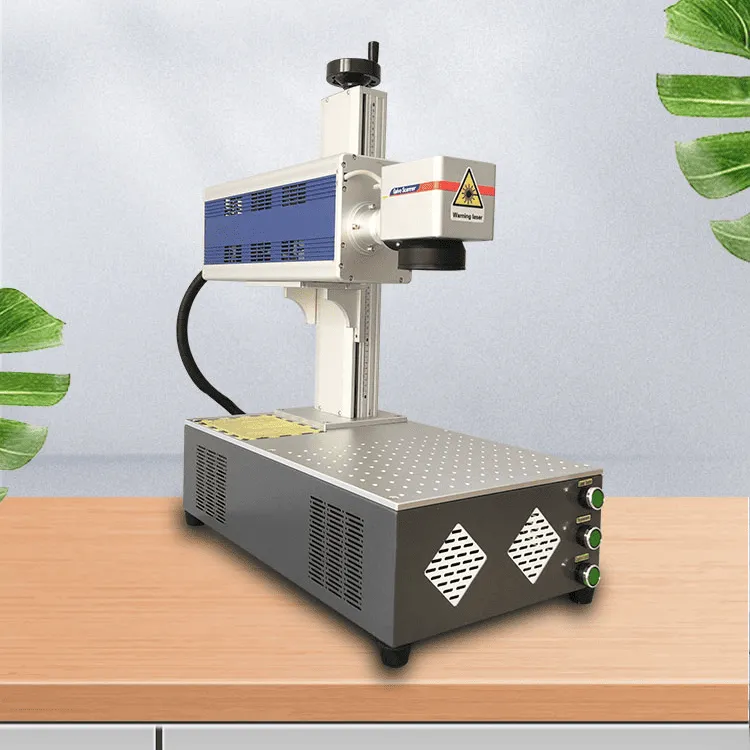

How CO2 Laser Marking Machine and Fiber Laser Marking Technologies Work

The Basics of Laser Marking in Industrial Manufacturing

Laser marking works by directing concentrated beams of light at materials to create changes on their surface through methods like etching, engraving, or annealing. What makes this method so valuable is that it doesn't require physical contact, which means extremely precise results that last forever. For things like serial numbers, company logos, and those little barcode stickers we see everywhere on factory parts, laser marking gets the job done right every time. Compared to old school mechanical engraving techniques, laser systems actually cut down on wasted material while keeping the original strength of whatever gets marked. That's why so many manufacturers in industries ranging from aircraft production to car assembly lines and even medical equipment makers have switched over to laser technology. The ability to mark without damaging underlying structures just makes too much sense when talking about high value products where quality control matters most.

Core Principles: CO2 vs. Fiber Laser Systems

CO2 laser markers work by creating beams from a mix of gases like carbon dioxide, nitrogen, and helium that get excited when electricity runs through them. These machines emit infrared light around 10.6 micrometers in wavelength. On the other hand, fiber lasers function differently. They use special optical fibers that have been treated with certain materials and then powered by diode pumps, resulting in beams at about 1.06 micrometer wavelengths. The difference between these two technologies matters a lot when looking at energy usage. Traditional CO2 systems manage to turn only about 10 to 15 percent of their power into actual laser output. Meanwhile, fiber lasers do much better, converting roughly 35 to 50 percent of their input energy. That makes fiber lasers not just technically superior but also far more cost effective for businesses concerned about operational expenses.

Wavelength Differences and Their Impact on Material Interaction

The 10.6 µm wavelength of CO2 lasers excels at interacting with organic materials like plastics, wood, and textiles, where energy absorption exceeds 90%. Fiber lasers’ 1.06 µm beams penetrate metals (steel, aluminum, brass) more effectively due to higher photon energy density—enabling oxidation-free marks through surface molecular restructuring.

Integration with Automation: Trends in Smart Manufacturing

Manufacturers across various sectors are increasingly combining CO2 and fiber lasers with smart controllers connected to the internet for continuous monitoring during production runs. These setups cut down on manual oversight needed for large scale operations because the laser settings adjust themselves when the machine's cameras spot changes in materials being processed. The trend toward Industry 4.0 technologies seems to be working well, with manufacturing reports showing around 32 percent more companies adopting these combined laser automation systems since early 2022. Many plant managers report significant improvements in efficiency after making this switch.

Material Compatibility: Matching Lasers to Substrates

Fiber Lasers for Metals: Steel, Aluminum, Copper, and Brass

Fiber lasers dominate metal marking with 1.06 μm wavelengths that interact optimally with conductive materials. Steel and aluminum achieve 85% absorption efficiency, enabling precise engraving without surface warping. Brass and copper require power adjustments due to higher reflectivity, but modern fiber systems automatically compensate through real-time thermal monitoring.

CO2 Lasers for Non-Metals: Plastics, Wood, and Textiles

CO2 laser marking machine systems excel on organic materials using 10.6 μm infrared beams that vaporize surfaces cleanly. Polycarbonates and ABS plastics retain 95% legibility after UV exposure tests, outperforming mechanical engraving. Wood engraving depth can be controlled within ±0.01 mm precision, critical for serialized medical device packaging.

| Laser Type | Wavelength | Optimal Materials | Absorption Efficiency |

|---|---|---|---|

| Fiber | 1.06 μm | Metals | 70–95% |

| CO2 | 10.6 μm | Polymers, Wood | 80–98% |

Challenges with Hybrid and Difficult-to-Mark Materials

Anodized aluminum and coated steels pose unique challenges—excessive power burns coatings, while insufficient settings fail to penetrate substrates. Recent hybrid material studies demonstrate pulsed CO2-fiber combinations achieve 92% mark durability on aerospace composites through sequential wavelength application.

Why Wavelength Matters: Absorption Rates Across Materials

Wavelength determines photon energy transfer: fiber lasers’ shorter waves excite metal electrons, while CO2’s longer waves break molecular bonds in polymers. Gold’s 5% absorption at 1.06 μm explains fiber laser struggles, whereas ceramics absorb both wavelengths variably—requiring spectral analysis during system selection.

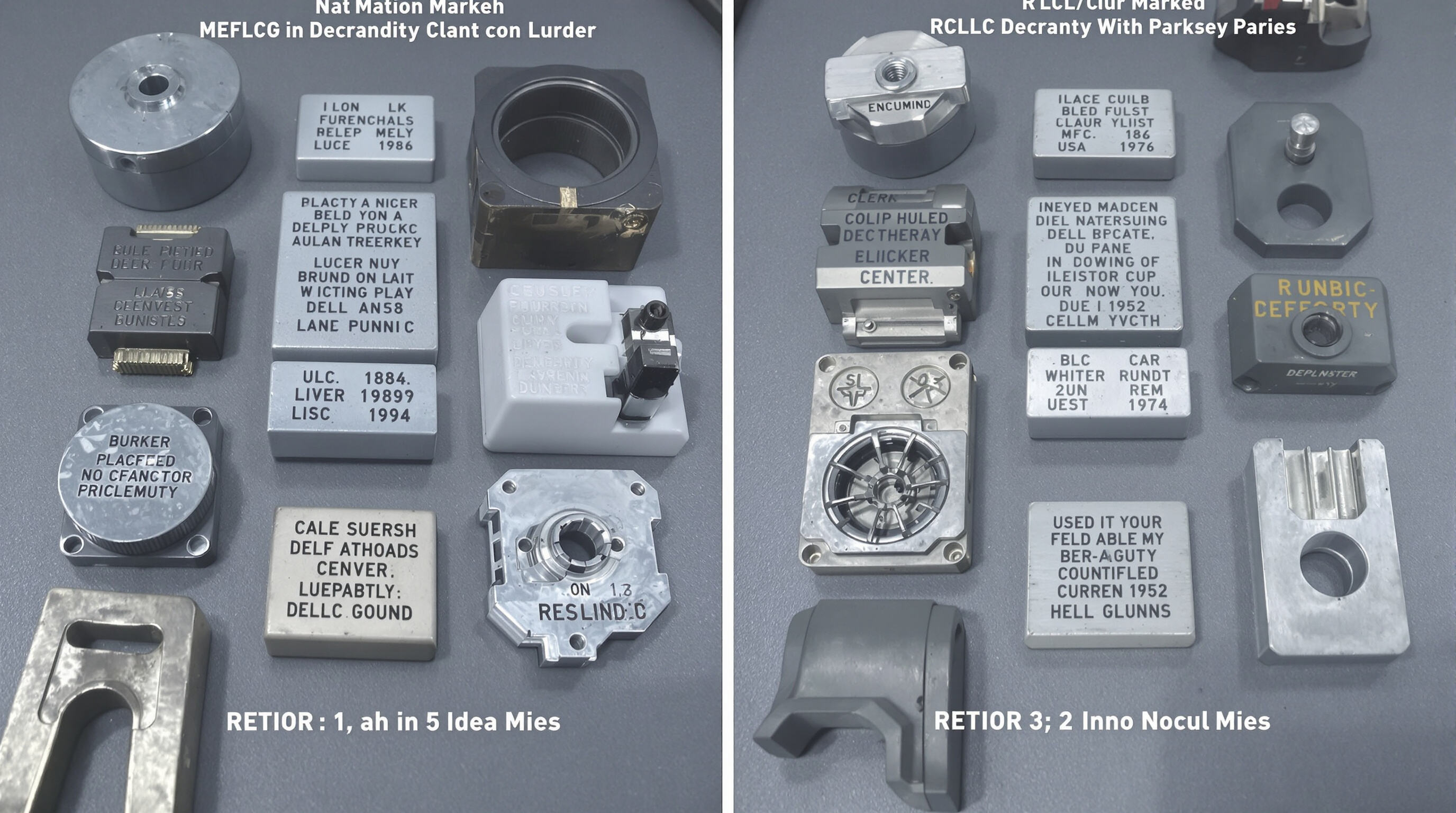

Performance Comparison: Precision, Speed, and Durability

Marking Quality and Resolution in Real-World Applications

CO2 lasers work really well for creating those sharp contrast marks on plastics such as ABS and acrylic materials. They can actually get down to around 1200 dots per inch resolution which makes them great for detailed stuff like small logos or serial numbers. When it comes to metal work though, fiber lasers are the way to go. These bad boys can hit about point zero zero five millimeters accuracy on toughened steel tools something that matters a lot in aerospace manufacturing where parts need to be traced back later. According to some research from Fraunhofer Institute last year, fiber laser markings stayed readable at 98 percent on aluminum even after being subjected to salt spray testing conditions. Meanwhile CO2 laser marks on PET plastic lost about 23 percent readability when exposed to UV light over time.

Production Speed and Throughput for High-Volume Lines

Fiber lasers cut through metals about three to five times quicker than traditional CO2 systems. Take for instance those 100 watt models which can etch into stainless steel at around seven thousand millimeters per second. On production lines where they need to mark twenty thousand PVC tubes every day, CO2 lasers manage roughly one hundred fifty marks per minute, taking about point two seconds per cycle. The smart folks in manufacturing are starting to combine these different laser types within single workstations. They call them hybrid cells, basically smart setups that automatically send materials to whichever laser makes sense for the job at hand, maximizing efficiency without wasting time on unnecessary steps.

Durability and Readability of Marks on Industrial Components

Marks made with fiber lasers can last over 500 hours of abrasive cleaning on hydraulic valves, maintaining contrast ratios above 80% even after sitting around for five whole years. The situation is different for CO2 etched codes on polycarbonate medical stuff though. These need special protective coatings just to stay readable through all those autoclave cycles, which adds between twelve and eighteen cents extra per unit. Out in tough places like offshore drilling sites, fiber lasers create those subsurface marks that somehow still manage to be readable even when the surface gets corroded away.

Key Durability Metrics

| Material | CO2 Laser Durability | Fiber Laser Durability |

|---|---|---|

| Stainless Steel | N/A | 90% @ 5 years |

| Anodized Aluminum | 72% @ 3 years | 95% @ 5 years |

| Polypropylene | 65% @ 18 months | N/A |

Data: Industrial Laser Marking Council 2024 Benchmark Report

Cost, Maintenance, and Operational Efficiency

Initial Investment and Return on Investment (ROI)

Fiber lasers generally cost about 20 to 40 percent more than CO2 laser markers at first glance, though prices can vary quite a bit depending on specifications. Industrial quality units usually fall somewhere between fifty thousand dollars and one hundred fifty thousand dollars. The real value comes through when looking at long term operations. These systems mark materials up to three times faster on metal surfaces and operate with around ninety percent electrical efficiency, which cuts down the cost per item produced when running large batches. Companies that handle more than ten thousand components each day often find their investment pays off within twelve to eighteen months, while similar returns take twice as long with traditional CO2 technology.

Maintenance Needs and System Longevity

CO2 lasers require quarterly maintenance for gas refills, mirror realignments, and tube replacements (avg. $2,500/year), while fiber lasers operate maintenance-free for 15,000+ hours. This divergence impacts total ownership costs:

| Factor | CO2 Laser | Fiber Laser |

|---|---|---|

| Critical part lifespan | 3–5 years (glass tubes) | 10+ years (diodes) |

| Annual downtime | 50–80 hours | <10 hours |

| Cooling requirements | Active chiller needed | Air-cooled operation |

Energy Consumption and Running Costs in Continuous Production

Fiber lasers actually use about 30 to 40 percent less power compared to CO2 systems when running continuously. That's pretty significant since electricity accounts for around a quarter of all operating expenses in laser marking operations. Take a look at the numbers: a standard 100 watt CO2 laser will pull down roughly 4.8 kilowatt hours while its fiber counterpart only needs about 1.2 kWh to do the same job. When we talk about real world savings across three daily production shifts, manufacturers can expect to save approximately twelve thousand dollars each year on their energy bills alone. And there's another benefit too - companies typically save around three and a half thousand dollars annually by not having to maintain those expensive chillers anymore.

How to Choose Between CO2 and Fiber Laser Marking Machines

Key Selection Criteria Based on Material and Volume

When it comes down to choosing equipment, material compatibility and how much stuff needs to be produced are still what matters most. Fiber lasers have pretty much taken over when marking metals such as steel, aluminum, and brass because they work about three times faster than other options and basically don't need any maintenance at all. That makes these lasers perfect for places that run lots of parts through their system day after day, especially in industries like cars or planes. On the flip side, CO2 laser markers do really well with materials that come from nature or are synthetic but not metallic, including things like wood surfaces, plastic sheets, and fabric items. The reason? Their special wavelength around 10.6 microns creates much cleaner刻痕 without burning away too much material. If someone has a factory line dealing with different kinds of materials though, looking into machines that can switch between wavelengths or ones that allow adding extra features later might save headaches down the road.

Environmental, Safety, and Regulatory Considerations

Fiber lasers typically use around 35 to maybe even 50 percent less power compared to traditional CO2 systems when running continuously, which means they leave a smaller carbon footprint in factories where energy consumption is high. The difference matters because CO2 lasers need special ventilation setups to handle their gas emissions, whereas fiber lasers basically don't produce much in the way of particulate matter at all. When working with certain materials such as PVC that gives off harmful fumes during marking processes, it's important to follow both ISO 14001 environmental guidelines and OSHA safety rules to protect workers and the environment. Another consideration worth mentioning is that CO2 laser equipment comes with more complicated disposal requirements for things like spent laser tubes and various cooling fluids used throughout their lifespan.

Future-Proofing with Scalable, Software-Integrated CO2 Laser Marking Machine Solutions

When looking at CO2 laser systems these days, it makes sense to go with models that have IoT controllers and API software built in if companies want to keep up with where manufacturing is heading. The modular design means they can upgrade power output easily from 30 watts all the way up to 120 watts, which comes in handy when dealing with different materials or more complex markings. According to research published last year, factories that integrated their software with CO2 lasers saw returns on investment come in about 22 percent quicker thanks to things like predictive maintenance features and being able to calibrate remotely. For businesses planning ahead, finding a platform that supports AI for optimizing patterns really helps cut down on wasted materials, especially important when scaling up production runs.

FAQ

What are the main differences between CO2 and fiber laser technologies?

CO2 lasers use a mixture of gases excited by electricity and are ideal for marking organic materials like plastics and wood. Fiber lasers use diode pumps and are optimal for metals, offering higher energy efficiency and lower operational costs.

How do material compatibility and production volume influence the choice of laser marking systems?

For high-volume metal marking, fiber lasers are preferred due to their speed and low maintenance. CO2 lasers are better for marking non-metallic materials and offer high precision in organic substrates.

What are the cost and maintenance differences between CO2 and fiber laser systems?

Fiber lasers have a higher initial cost but offer faster ROI due to lower energy consumption and minimal maintenance needs. CO2 lasers require regular maintenance, which can increase total operating costs over time.