How 3D Crystal Engraving Machines Technology Transforms Crystal Art

Understanding the 3D Laser Engraving Process and Its Core Mechanics

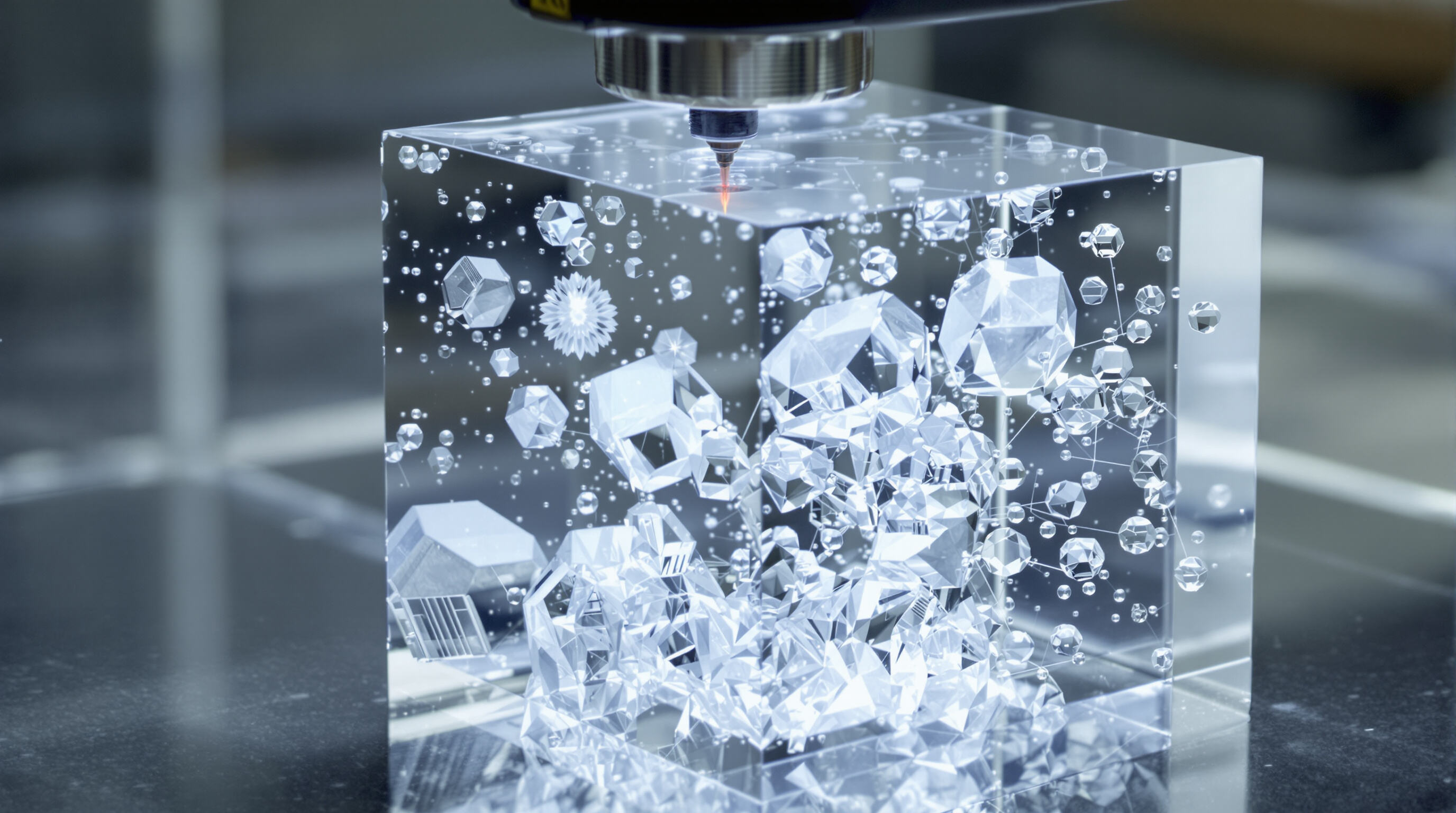

Crystal engraving machines today rely on focused laser beams to carve out three dimensional designs inside clear materials by modifying what's beneath the surface. Surface level engravings are just two dimensional, but these modern techniques send ultra fast laser pulses into specific spots deep within the crystal itself. The pulses last only femtoseconds or picoseconds, which is super short. When they hit those target areas, they create tiny fractures through something called nonlinear absorption. What happens next is pretty cool. These fractures form lasting patterns inside the crystal that we can actually see because light gets scattered differently at those modified points. Think of it like creating hidden art inside glass that becomes visible when light hits it from certain angles.

Sub-Surface Laser Engraving in Transparent Materials: How Light Interacts With Crystal

High quality crystal materials let laser beams go through about 10 centimeters thick without losing their sharpness. What happens next is pretty interesting stuff. When there's enough photons packed together beyond what the crystal can handle, little pockets of plasma start forming inside. These tiny holes range from about 5 to 20 micrometers in size and mess with how light travels through the material. That's why when something gets etched into these crystals, it looks like the design is floating somewhere inside instead of just sitting on the surface. The really fancy machines out there actually adjust how strong the laser beam is as it moves through different layers of the crystal. This lets manufacturers create all sorts of cool visual tricks, from barely visible faint images to bold three dimensional effects that pop right out at you.

Layer-by-Layer Ablation Process: Building Depth Through Precision Pulses

Top quality machines can hit pretty impressive dimensional accuracy around plus or minus 0.01 mm when they mix galvo scanners that move beams fast with piezoelectric stages that handle those tiny Z-axis movements at the micron level. Let's take a standard one inch cube as an example. These usually need somewhere between twenty and fifty different layers stacked on top of each other, and each layer gets built using anywhere from five hundred to two thousand individual laser shots. The folks running these machines tweak things like pulse energy levels ranging from 0.1 to 10 microjoules and adjust how often the laser fires, typically between one and one hundred kilohertz. This balancing act lets them get resolutions down to about 200 dots per inch while still managing engraving speeds that generally fall somewhere between fifteen and ninety minutes for each item produced.

How 3D Engraving Differs From 2D Engraving in Methodology and Outcome

Traditional 2D engraving methods use CO2 lasers that only create shallow carbonized marks on surfaces, typically no deeper than half a millimeter. But when we move into 3D crystal engraving territory, things get much more interesting. These advanced techniques can actually carve intricate designs inside the crystal itself, reaching depths of around 10 centimeters. What makes this so special? The result creates real parallax effects where different parts of the design appear to change position as someone turns the crystal around in their hands. A recent look at materials science from early 2024 found something fascinating too. Crystals with 3D engravings let through almost all the light they receive, maintaining about 98% transmission. Regular 2D engravings only manage around 85%. That means these deeper engravings offer much better optical quality, which explains why luxury brands prefer them for high-end products.

Key Components of Crystal Engraving Machines for High-Precision Results

Laser Engraving Machine Components That Enable High-Precision 3D Work

Crystal engraving machines today typically come with four main components working together. First there's the laser module capable of hitting sub-10 micrometer wavelength accuracy. Then we have dynamic Z-axis focusing parts that adjust on the fly, paired with air cooled galvo scanners for movement control, plus real time monitoring sensors keeping track of everything. When all these parts work in harmony, they achieve around plus or minus 5 micrometers of repeatable positioning which is really important when doing complex 3D engravings across multiple layers. The top end machines are starting to feature special thermal compensation systems too. These help fight against crystal expansion issues that happen during long engraving sessions. According to industry data from the latest Laser Engraving Technology Report published in 2024, this kind of thermal management cuts down defects by about a quarter compared to regular equipment without such features.

Role of Laser Power, Focus, and Speed Control for Depth Variation

Getting different depths right needs careful balancing act among several factors. Laser power settings range from 15 to 60 watts, while adjusting the focal depth can be done in increments as small as 0.1mm up to 25mm. Scanning speed also plays a big role, varying between 50 and 2,000 mm per second depending on what's needed. Modern equipment has gotten pretty good at handling these changes quickly too. Some advanced models can switch modes in just 0.01 seconds, making it possible to go from creating very shallow textures under 0.2mm deep right into deeper cuts exceeding 8mm without missing a beat. Testing in real world conditions has shown that systems using closed loop power monitoring maintain depth consistency within plus or minus 2% throughout entire production runs. That represents about a 15% boost compared to older open loop systems, which means fewer rejects and better quality control overall for manufacturers.

Importance of Motion Control Systems and Calibration in Crystal Engraving Machines

Getting precise results depends heavily on linear motor stages that can position things within half a micrometer and keep angular deviations below 0.001 degrees. When we talk about modern calibration techniques, laser interferometry really helps cut down those pesky alignment errors to less than one micrometer per meter. This matters a lot when working with big crystal formations that can reach sizes of around 300 cubic millimeters. For the most recent motion control systems, they actually perform five axis corrections at an impressive rate of 1,000 times per second. This high frequency correction makes all the difference when dealing with intricate three dimensional shapes or curved surfaces where even small errors would create visible flaws in the final product.

Software Integration and System Stability in Professional-Grade Machines

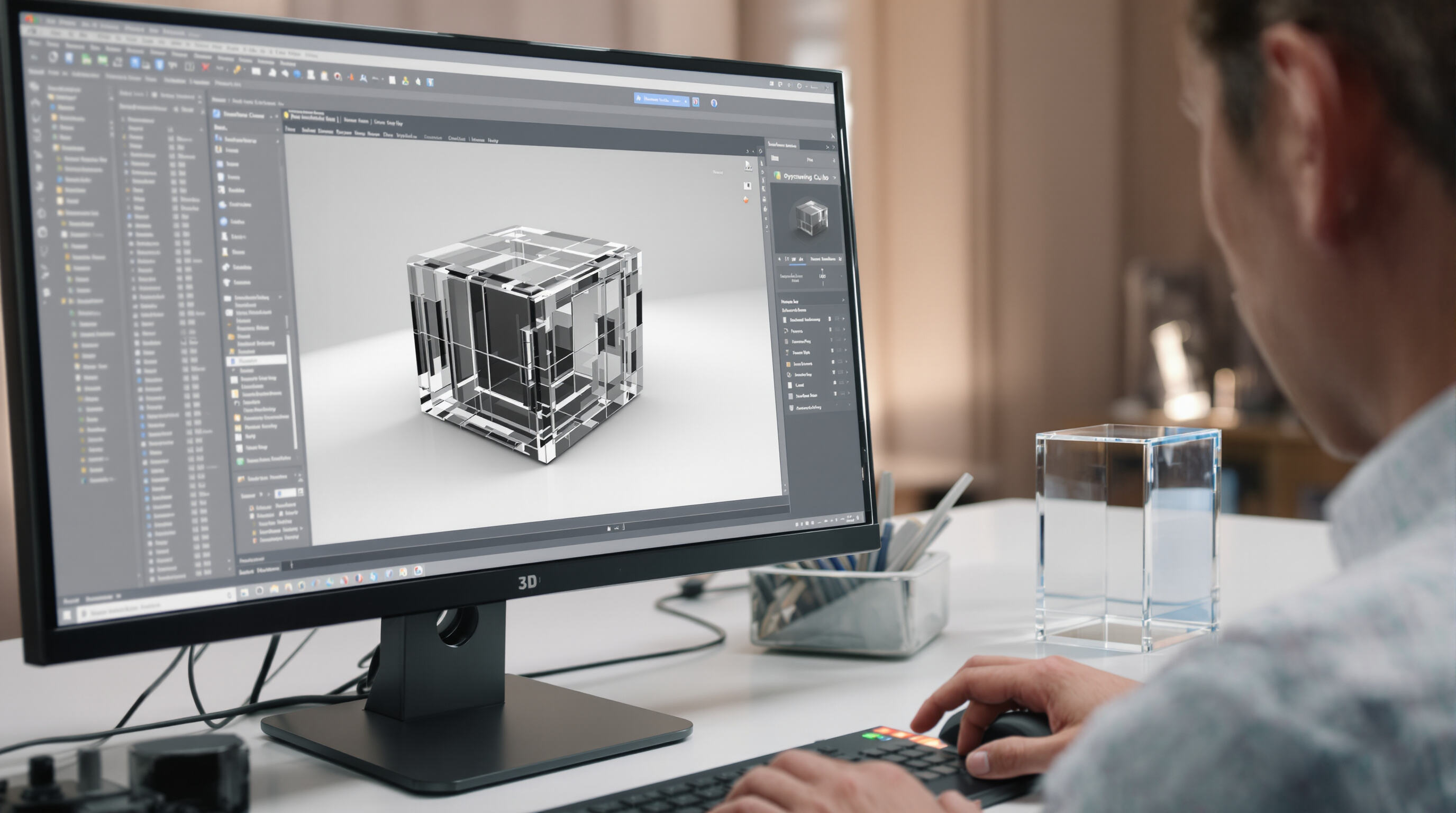

Custom made software takes those 3D model designs and turns them into actual machine commands through something called adaptive layer slicing. These algorithms tweak the energy levels from around 5 to 100 joules per square centimeter depending on how complicated the geometry gets. When it comes to getting sharp edges right, our real time vibration damping system makes a noticeable difference. We've seen edge quality improvements of about 18 percent when dealing with those fast moving patterns between 200 and 500 kilohertz frequencies. And let's not forget about maintenance planning. Our special health monitoring tech can spot when parts start wearing out with pretty impressive accuracy rates around 94%. That kind of predictive capability helps explain why most industrial units last anywhere from seven to ten years before needing major overhauls.

From 2D Image to 3D Masterpiece: Grayscale Mapping and Design Conversion

Grayscale Image Processing for Depth Mapping in Crystal Designs

Crystal engraving machines take ordinary flat images and turn them into stunning 3D masterpieces. They do this by reading the different shades of gray in an image and turning those into instructions for how deep to cut into the crystal. Think about it like this: when there are really dark areas in the picture, the machine knows to go deeper into the material, whereas lighter parts just get a gentle touch on the surface. According to research published last year by the Smithsonian ArtTech Institute, these machines actually create artwork that's three times more accurate dimensionally than what someone could achieve by hand carving alone. That's quite impressive considering how much detail can be lost during traditional methods.

Using Grayscale Height Maps for 3D Engraving Precision

Height maps—specialized grayscale images where brightness corresponds to elevation—guide lasers in creating slopes, ridges, and recesses with 0.01mm vertical resolution. Designers often stack multiple maps to render intricate features like facial contours in memorial pieces or topographic detail in architectural miniatures.

Software Algorithms That Translate 2D Images into Multi-Layer 3D Models

Proprietary software automates conversion using edge detection and voxel-based modeling. For a standard 4" crystal cube, these tools generate 120–150 discrete layers from a single 2D input, preserving shadow details through adaptive power modulation. AI-driven prediction engines now compensate for light refraction distortions inherent in crystal substrates, enhancing final image fidelity.

Limitations of Current Grayscale Rendering in Ultra-Fine Detail Applications

Despite broad effectiveness, grayscale conversion faces challenges with sub-50 micron features—such as eyelashes in portraits or text smaller than 8pt—which often lose clarity. The 256-shade limit can also produce visible banding in gradient-rich designs like sunsets, requiring manual refinement for smooth tonal transitions.

Designing Visually Striking and Durable 3D Crystal Engravings

Balancing Aesthetic Appeal With Structural Integrity in Crystal Art

Creating compelling crystal art demands harmony between design ambition and material limits. Machines maintain ±5 µm precision—verified by NIST 2023 standards—to avoid microfractures that weaken the structure. Designers strategically distribute engraving depths, preserving 60–70% of original mass in high-stress zones while using shadowed regions to enhance perceived depth.

Multi-Layer Engraving for 3D Effects That Enhance Visual Depth

Up to 15 distinct layers are carved using pulsed lasers, each altering how light refracts through the crystal. Research published in Optical Materials Journal (2022) found deeper layers contribute 68% of perceived depth, enabling rich volumetric effects without exceeding fracture thresholds.

Precision and Permanence in Crystal Engraving as a Hallmark of Quality

Professional results depend on three key factors: optimized laser wavelength (532nm green lasers dominate crystal applications), thermal management keeping substrate temperatures below 120°C, and 0.001° incremental rotation control for uniform omnidirectional engraving.

Best Practices for Optimizing Clarity, Contrast, and Durability

Top manufacturers recommend:

- Using 80–120W laser power for controlled material removal

- Applying 25–40% grayscale gradients to maximize depth perception

- Performing post-engraving ultrasonic cleaning (3–5 minutes at 40kHz)

- Applying anti-reflective coatings to boost 3D visibility by 35%

Applications and Market Trends in 3D Crystal Engraving

The capabilities of modern crystal engraving machines have expanded personalized manufacturing, with industry revenue projected to reach $250 million by 2033 at a 9.2% CAGR (Verified Market Reports 2024). This growth reflects adoption across luxury goods, corporate gifting, and artistic installations.

Applications of 3D engraving in art and design: sculptures and installations

Artists use sub-surface engraving to create light-responsive sculptures and museum installations. A single crystal can contain over 50,000 precisely placed laser points, forming depth-rich compositions that interact dynamically with ambient lighting. The 2024 Biennale of Glass Art featured 12 exhibits using this technique, signaling its rising status in contemporary art.

Personalized luxury items: custom awards, gifts, and corporate keepsakes

According to Market Research Intellect's latest data from 2024, around 42 percent of all commercial machines are being used in the high-end gift market these days. People want custom trophies that have those cool 3D logos, memorials that actually capture fingerprints in incredible detail, and wedding presents where portraits look almost lifelike with multiple layers. The technology has gotten really good too. These days, machines can render faces with such precision down to just 0.1 millimeters that when they engrave someone's face, it looks almost exactly like a photo. Some folks say it's like magic how realistic these images turn out now.

Case Study: DEZHOU QIJUN AUTOMATION EQUIPMENT CO., LTD’s impact on commercial crystal art

A leading Chinese manufacturer’s 2023 product line demonstrates how industrial-grade systems have made advanced engraving more accessible. Their hybrid laser platforms reduced production time for complex 3D awards by 68% while maintaining <0.05mm accuracy. Independent testing confirmed their patented cooling system increased machine uptime by 22% in high-volume trophy environments.

Trend Analysis: Rising demand for bespoke 3D crystal products in premium markets

North America represents 38% of global crystal engraving machine sales, fueled by demand for customized jewelry displays, architectural scale models, and branded crystal components in luxury vehicles. Industry analysis shows 74% of premium buyers prioritize "technical craftsmanship" when selecting engraved crystal goods, sustaining market demand for systems capable of 200+ layer engravings.

FAQs about 3D Laser Engraving Technology

What is 3D laser engraving?

3D laser engraving involves using focused laser beams to etch designs inside clear materials, creating intricate patterns that can be viewed from various angles.

How does 3D engraving differ from 2D engraving?

Unlike 2D engraving, which creates shallow surface marks, 3D engraving allows for intricate designs inside the material, offering better optical quality and depth perception.

What materials are typically used for 3D laser engraving?

High-quality transparent materials, such as crystal, are commonly used because they allow laser beams to pass through without losing sharpness, enabling deep engravings.

What are the main components of a 3D laser engraving machine?

These machines typically have a laser module, dynamic Z-axis focusing parts, air cooled galvo scanners, and real-time monitoring sensors to achieve high precision engravings.

What are the applications of 3D crystal engraving?

3D crystal engraving is used for personalized luxury items, custom awards, corporate gifts, sculptures, and artistic installations, among others.

Table of Contents

- How 3D Crystal Engraving Machines Technology Transforms Crystal Art

- Key Components of Crystal Engraving Machines for High-Precision Results

- From 2D Image to 3D Masterpiece: Grayscale Mapping and Design Conversion

- Designing Visually Striking and Durable 3D Crystal Engravings

-

Applications and Market Trends in 3D Crystal Engraving

- Applications of 3D engraving in art and design: sculptures and installations

- Personalized luxury items: custom awards, gifts, and corporate keepsakes

- Case Study: DEZHOU QIJUN AUTOMATION EQUIPMENT CO., LTD’s impact on commercial crystal art

- Trend Analysis: Rising demand for bespoke 3D crystal products in premium markets

- FAQs about 3D Laser Engraving Technology