Enhanced Welding Speed and Operational Efficiency

30% faster: The focused heat source brings together the process benefits of 30% higher welding speed with top edges and very fast welding. This speeds up joint preparation with improved weld integrity (the sheet metal industry reports 3.2 minutes per meter cycle time reduction on average) (Ponemon 2023). The technology’s pulsed operation mode eliminates delays due to tooling repositioning and allows a steady 12 meters per minute welding speed in automotive assembly.

Continuous Welding Capabilities for Production Lines

Integrated CNC controls and robotic articulation systems allow uninterrupted 24/7 operation, critical for high-volume manufacturing. A 2024 aerospace production analysis revealed a 35% output improvement when switching from resistance welding to continuous laser systems. This seamless workflow minimizes bottlenecks while maintaining ±0.1mm positional accuracy across 8-hour shifts, eliminating manual recalibration needs.

Unmatched Portability and Compact Design

Modern portable laser welders redefine industrial mobility through ergonomic engineering and space-conscious designs. Weighing up to 70% less than traditional systems, these devices combine robust aluminum frames with vibration-dampening grips for single-operator workflows. Their compact footprint—often comparable to cordless power tools—enables precise maneuverability in tight spaces.

Ergonomic Handheld Laser Welder Configurations

Engineers prioritize balanced weight distribution through modular layouts, allowing 8+ hours of continuous use without operator fatigue. Features like swiveling fiber optic cables and magnetic safety glasses enable rapid repositioning during overhead or vertical welding tasks. Integrated cooling systems maintain thermal stability in confined environments while eliminating external chillers.

On-Site Repair Applications in Aerospace Industry

Aerospace technicians leverage portability for wingtip-to-landing-gear repairs without disassembly. Field tests show handheld laser units complete turbine blade crack repairs 58% faster than TIG methods. The absence of gas cylinders and 24V battery compatibility permits runway-side operations, minimizing aircraft downtime during critical maintenance.

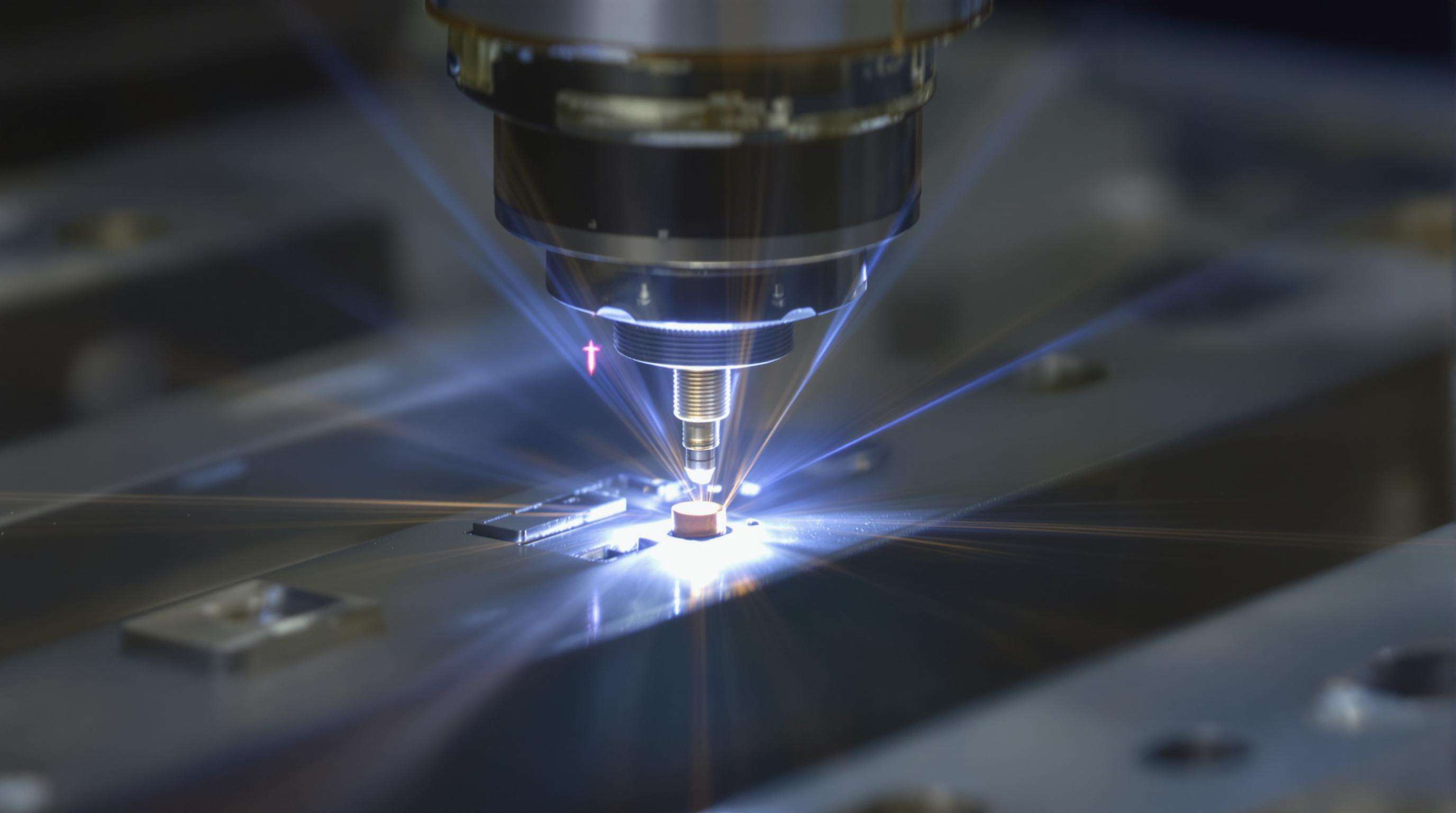

Precision Engineering with Minimal Heat Impact

0.5mm Beam Diameter for Micro-Welding Applications

Laser welders achieve precision unmatched by traditional methods, with focused beams as narrow as 0.5mm enabling welds as fine as 0.2mm in medical-grade components. This capability is critical for aerospace instrumentation and implantable medical devices, where joints must maintain submillimeter tolerances.

Heat-Affected Zone Reduction in Thin Materials

Advanced pulse shaping reduces the heat-affected zone (HAZ) by 62% compared to TIG welding (2023 Materials Processing Report). In materials under 1mm thickness—common in battery enclosures—this prevents warping and preserves tensile strength. Real-time thermal monitoring adjusts energy delivery within ±3% accuracy, ensuring materials retain 95% of original properties.

Case Study: Medical Device Component Welding

A titanium alloy neurostimulator project demonstrated laser welding’s superiority:

- Distortion: 80% less than resistance welding

- Post-weld cleanup: Eliminated due to spatter-free joins

-

Production yield: Increased from 82% to 98%

The process met ISO 13485 cleanroom standards while reducing per-unit energy costs by 44%.

Versatile Material Compatibility and Positioning

Multi-Alloy Welding from Aluminum to Titanium

Laser systems seamlessly join aluminum (5000-7000 series) to titanium grades like Ti-6Al-4V without flux additives. Recent multi-material fabrication research reveals 95% joint efficiency across dissimilar materials through precise energy modulation. The technology’s 50–200 µs pulse control prevents brittle intermetallic phases when bonding copper alloys to stainless steel.

Overhead and Vertical Welding Configurations

Portable laser welders enable stable 360° joint access with ̰0.1 mm beam drift. Field tests show a 60% reduction in setup time for vertical seams, as operators no longer require complex fixturing. The systems’ <2° beam divergence maintains <10% energy loss in overhead orientations, crucial for shipyard piping and power plant maintenance.

Clean Welds with Reduced Post-Processing

Spatter-Free Joining in Automotive Panels

Laser welding eliminates spatter through precise energy control, reducing post-weld cleaning by up to 90%. This enables immediate progression to painting stages, particularly in high-volume electric vehicle chassis assembly.

Surface Finish Quality Comparisons

Laser-welded joints exhibit 60% fewer surface irregularities than arc-welded counterparts. Micrograph evaluations reveal near-net-shape surfaces with roughness averages matching base materials, allowing manufacturers to skip polishing phases while maintaining tolerances under 0.2mm.

Energy Efficiency and Operational Cost Savings

Power Consumption vs. Conventional TIG Welding

Handheld laser welders use 40-50% less energy than TIG systems, requiring 12-15 kW for tasks that typically demand 20-25 kW. A 2024 analysis showed laser welding reduced monthly energy expenses by $540 per workstation in automotive fabrication.

Long-Term Maintenance Cost Analysis

The simplified optical architecture slashes component replacement costs by 30-35% over five years compared to conventional systems. Without consumable electrodes or gas regulators, facilities eliminate $2,800-$3,200 in annual material costs per unit. Laser welders average 12,000 operational hours between servicing—triple the lifespan of TIG systems

FAQs

What are the main advantages of using laser welding?

Laser welding offers enhanced welding speed, unmatched precision, and energy efficiency. It allows for continuous welding capabilities with minimal heat impact, while also being versatile with different materials.

How does laser welding save on operational costs?

Laser welding reduces energy consumption, leading to lower monthly energy expenses. Additionally, the simplified optical architecture reduces long-term maintenance costs.

Can laser welders be used for portable applications?

Yes, modern portable laser welders are designed for industrial mobility, allowing for precise maneuverability and on-site repair applications, especially in industries like aerospace.