Applications in Automotive Manufacturing

Precision Welding for Engine Components

Handheld laser welders achieve 0.1 mm beam accuracy, essential for high-stress components like cylinder heads and exhaust manifolds. This precision enables full-penetration welds in cast iron and titanium alloys without thermal cracking, reducing post-weld machining by 60% compared to TIG methods while maintaining 450 MPa tensile strength.

Lightweight Material Joining in EV Production

For aluminum-carbon fiber hybrids, handheld lasers provide 200W-300W pulsed beams ideal for 0.8 mm thin sheets. The technology limits heat-affected zones to 0.3 mm, preventing warping in battery enclosure seams. A 2023 study showed laser-welded aluminum joints improve EV range by 12% versus mechanical fasteners.

On-Site Repairs for Production Line Efficiency

Portable laser systems allow technicians to repair robotic end-effector clamps or conveyor guides in 15 minutes versus 2+ hours for component replacement, reducing unplanned downtime by 35% annually in high-volume plants.

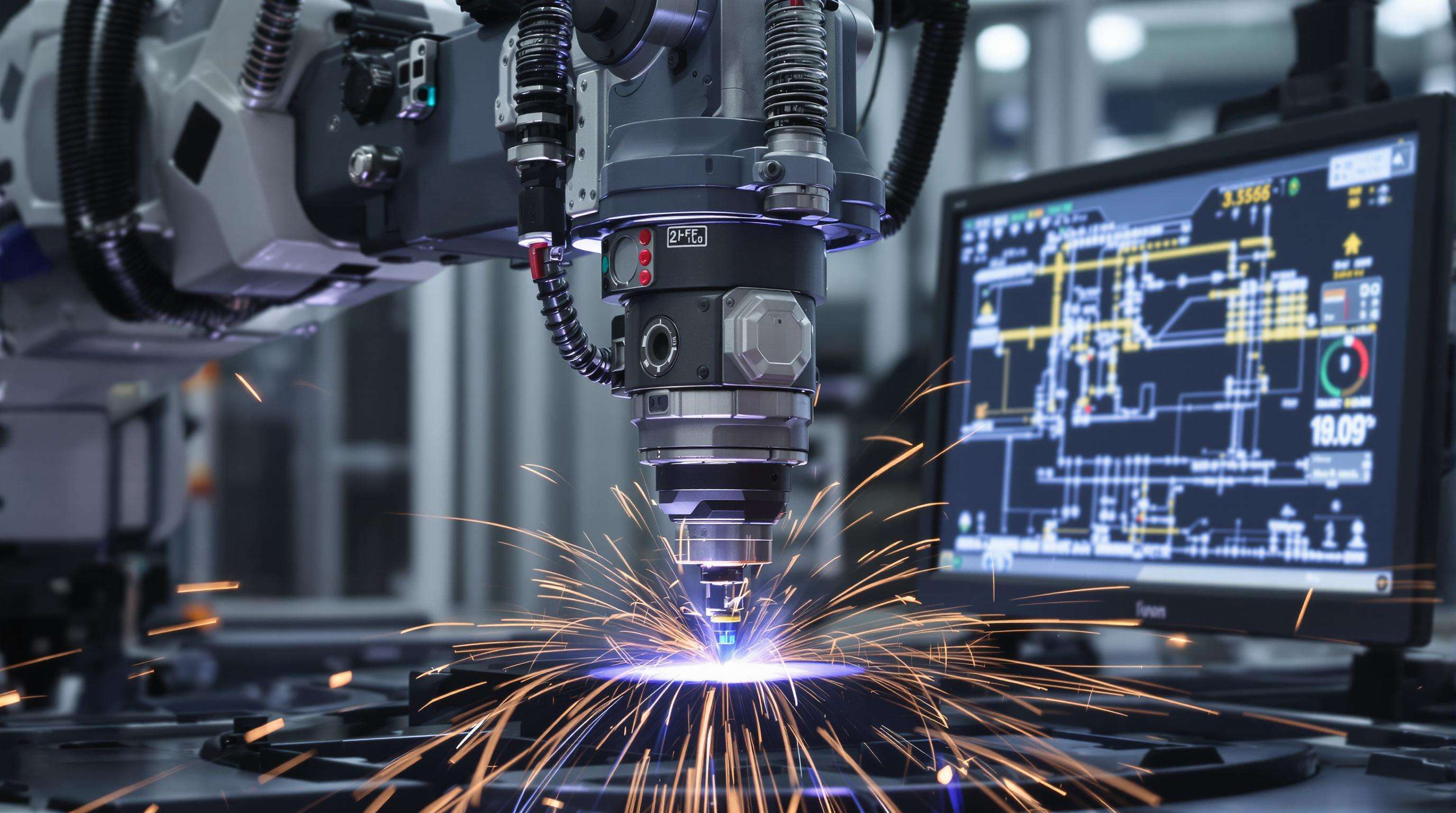

Automation Integration in Assembly Systems

Collaborative robots (cobots) with laser welding heads complete 87% of A-pillar welds in advanced body shops. Integrated vision systems auto-adjust power (500-1500 W) based on joint tracking, achieving 99.2% first-pass weld success rates and cutting rework costs by $18 per vehicle.

Aerospace Industry Applications

Handheld laser welders create seams with 98% density in critical aerospace components (NIAR 2023), enabling complex joins in confined spaces like fuel systems and wing boxes without disassembly.

Aerospace-Grade Aluminum Welding Solutions

For 2000/7000-series aluminum alloys, fiber lasers produce 0.1-0.3mm welds with 320 MPa tensile strength, exceeding FAA requirements. Pulse control (5-ms) prevents overheating in grades like AA7075, preserving corrosion resistance.

Minimizing Thermal Distortion in Thin Sheets

Laser systems reduce heat input by 80% versus TIG welding in aircraft skins <1.2mm thick. Real-time thermal imaging adjusts power on curved surfaces (e.g., engine nacelles), maintaining ±0.05mm flatness, key to a 45% adoption increase in wing manufacturing since 2022.

Structural Component Welding with Fiber Lasers

Multi-kilowatt handheld lasers penetrate 8mm titanium for engine mounts, achieving 12:1 depth-to-width ratios in single passes. A 2023 case study showed 30% faster production versus plasma arc welding for turbine blade repairs.

Medical Device and Electronics Applications

Micro-Welding for Sensitive Circuitry

Handheld lasers create 0.1-0.3mm welds on medical electronics without damaging heat-sensitive components. Titanium enclosures achieve 98.7% hermeticity for pacemakers, exceeding FDA standards. This precision supports biomedical sensing devices.

Sterile Environment Welding for Surgical Tools

Non-contact laser welding in ISO Class 5 cleanrooms eliminates particulate generation, cutting validation time by 40% versus arc welding. The process meets ANSI/AAMI ST79 standards for reusable instruments.

Multi-Material Fabrication

Steel-Aluminum Hybrid Welding Techniques

Fiber lasers minimize intermetallic formation (0.5-2.5 kJ/mm heat input), achieving 85% base material strength. A 2025 review highlights adaptive pulse shaping for automotive/marine components.

Portable Systems for On-Site Metal Repairs

Battery-powered lasers (150-300W output) enable 6mm-deep field repairs, reducing downtime by 65%. Automotive research confirms nitrogen-assisted shielding maintains 200 MPa fatigue resistance in suspension components.

AI-Powered Real-Time Parameter Adjustment

AI-driven systems dynamically optimize laser power and travel speed by analyzing joint configurations and material variations, reducing defects in precision-critical industries. Integration with IoT platforms enables continuous improvement, marrying manual flexibility with robotic repeatability.

FAQ

What is the benefit of using handheld laser welders in automotive manufacturing?

Handheld laser welders offer high precision for welding components like cylinder heads, reducing thermal cracking and post-weld machining, and provide efficiency in on-site repairs.

How do handheld laser welders contribute to EV production?

They provide precise welding for aluminum-carbon fiber hybrids, limiting warping in battery enclosures, which can improve EV range by up to 12%.

What advantages do laser systems offer in aerospace component manufacturing?

Laser systems allow for dense seams without disassembly, crucial for aerospace parts, and help in minimizing thermal distortion in thin sheet fabrication.

How do AI-driven systems enhance precision in laser welding?

AI optimizes power and speed by analyzing configurations, reducing defects and improving precision in key industries.