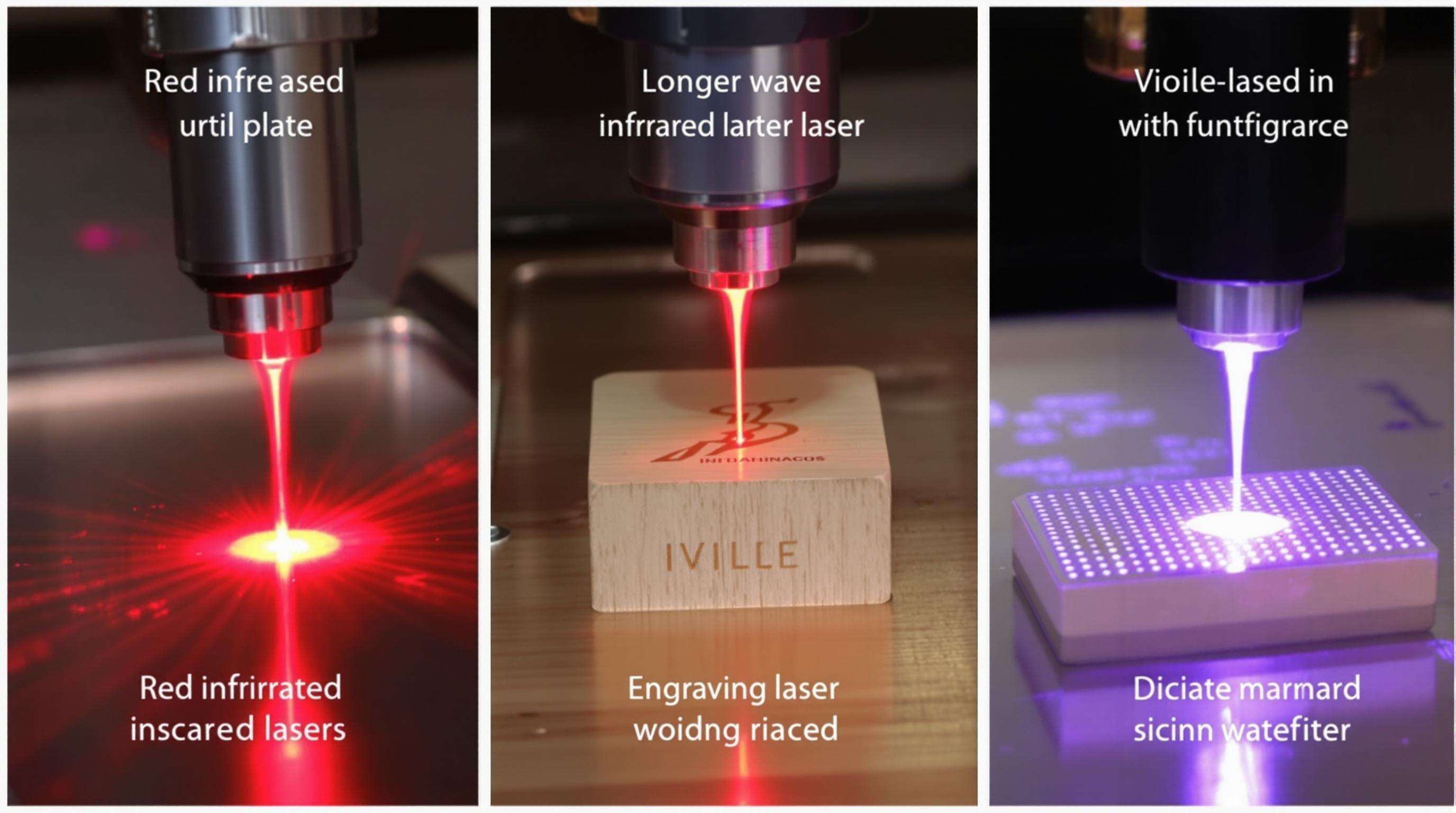

Wavelength Characteristics: Fiber vs CO₂ vs UV Lasers

Laser Technology Core Principles: Wavelength and Material Interactions

Uv laser marking performance depends on the relationship between wavelength and material absorption properties. Fiber Laser (800-2200 nm wavelengths) excel at marking metals like steel, aluminum, and titanium alloys, while CO₂ lasers (10.6 μm wavelength) target organic materials such as wood, acrylic, and textiles through vibrational energy transfer.

Key differences in material responses:

- Polished metals reflect up to 60% of incident laser energy (NIST 2023).

- Thermoplastics like ABS absorb UV laser wavelengths (355 nm) 30x more efficiently than infrared.

- UV lasers achieve ultra-fine marks (<5 μm resolution) on medical-grade silicone with minimal heat impact.

Three governing principles:

- Absorption depth – UV wavelengths interact within 0.1-10 μm surface layers.

- Photon energy thresholds – CO₂ lasers require 25 W·cm−² for polycarbonate vs. 450 W·cm−² for stainless steel engraving with fiber lasers.

- Thermal relaxation time – Delicate materials need pulse durations under 20 ns to avoid warping.

Modern systems now feature wavelength-adjustable modules for marking both metals (1064 nm) and plastics (355 nm), though specialized lasers still outperform in power density (220 kW·cm−² for dedicated fiber lasers).

Infrared Fiber Lasers: Deep Penetration for Metals

Infrared fiber lasers at 1064nm wavelengths, focus on metals with high accuracy. The long wavelength allows for the intrinsic photon absorption inside the metallic lattices, which makes the modification of the material inside the bulk possible. This deep penetration means the marks won’t just scratch off like in other marking processes resulting in a durable mark through backside annealing — the process of heating up metal to oxidize colors without affecting the metal itself. This process is used for industrial applications on stainless steel, titanium, and aluminum parts where wear resistance is important.

| Laser Type | Wavelength | Material Specialty |

|---|---|---|

| Fiber | 1064 nm | Metals & alloys |

| CO₂ | 10.6 μm | Organics |

| UV | 355 nm | Sensitive surfaces |

CO₂ Lasers: Optimal 10.6μm Wavelength for Organics

The 10.6-micrometer wavelength of CO₂ lasers aligns perfectly with molecular vibration frequencies in organic materials. This resonant absorption rapidly converts light energy into heat for controlled material removal through sublimation. Woods, acrylics, leather, and composite plastics efficiently absorb this infrared wavelength without scattering effects.

UV Lasers: Cold Marking via 355nm Photon Energy

UV lasers leverage high-energy 355nm photons to initiate photochemical reactions rather than thermal processes. This "cold marking" approach disintegrates molecular bonds without generating destructive heat zones. Sensitive electronics and medical components benefit from damage-free serialization and UDI codes.

Material Compatibility Breakdown

Metals & Alloys: Fiber Laser Dominance with VCS Technology

Fiber lasers leverage near-infrared wavelengths optimized for deep metallic absorption, making VCS (Vertical Cavity Surface Emitting) systems ideal for stainless steel, aluminum, and titanium. The 1064 nm frequency heats surfaces instantly, creating durable engraved serial codes or annealing marks resistant to abrasion and corrosion.

Wood/Glass/Plastics: CO₂ Laser Versatility

CO₂ lasers outperform alternatives on organics due to optimal 10.6 μm wavelength absorption. This wavelength excites molecular bonds in wood, acrylic, glass, and polymers, enabling fast engraving without charring. For PVC, ABS, and polycarbonate, adjustable settings prevent thermal deformation while maintaining FDA-legible codes for packaging.

Sensitive Electronics: UV Laser Micro-Marking Precision

UV lasers operate via non-thermal photochemical reactions, critical for silicon wafers, PCBs, or gold-coated connectors. Their 355 nm photons break atomic bonds without heat, achieving 25-μm alphanumeric serialization on resistors and microchips.

Industry-Specific Applications Comparison

Automotive: Fiber Lasers for Durable Part Identification

Fiber laser systems excel in marking engine blocks, transmission components, and vehicle identification numbers (VINs) where permanent traceability is critical. Their high peak power and infrared wavelengths penetrate metal surfaces without compromising structural integrity.

Medical: UV Lasers for UDI-Compliant Device Marking

Medical device manufacturers rely on UV lasers for meeting FDA Unique Device Identification (UDI) mandates. The 355nm wavelength creates micro-scale Data Matrix codes on surgical instruments and implants without generating heat-affected zones.

Electronics: UV Optibeam Technology for PCB Serialization

UV Optibeam technology achieves micron-level precision for marking printed circuit boards (PCBs) and semiconductor components. The photochemical ablation process etches scannable QR codes directly onto silicon wafers without thermal damage to surrounding circuitry.

Crafts: CO₂ Lasers for Organic Material Engraving

CO₂ lasers dominate artisanal applications with non-contact processing of natural media. Woodworkers and designers leverage 10.6μm wavelengths to vaporize cellulose in wood, leather, and acrylics at controllable depths under 0.1mm.

Thermal Impact & Marking Quality Analysis

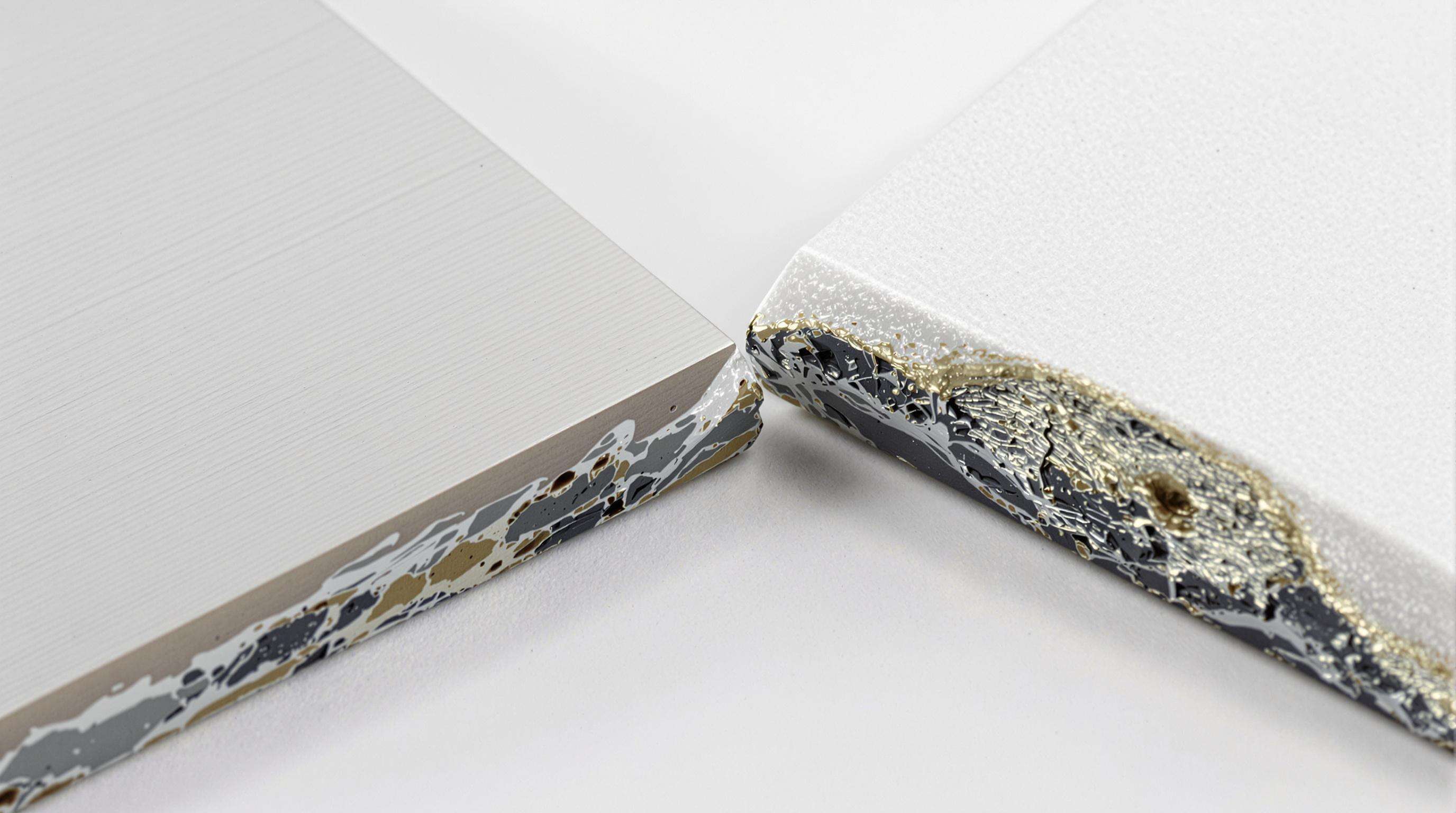

Annealing vs Ablation: Heat-Affected Zones Compared

Annealing and ablation marking methods generate significant thermal stress that alters material properties. During metal annealing, lasers heat surfaces to 750–1100°C, inducing oxidation through controlled thermal expansion. Ablation techniques vaporize organic materials like plastics, yet often leave charred edges and internal stress concentrations.

UV Cold Marking: Preserving Material Integrity

Unlike thermal processes, UV lasers operate through photochemical reactions that avoid heat transfer entirely. The 355nm wavelength delivers 3.5eV photon energy—sufficient to break molecular bonds but incapable of raising material temperatures significantly.

Regulatory Compliance Requirements

Medical Device UDI Standards: UV Laser Necessity

UV lasers enable UDI-compliant marking without compromising sterile packaging or bio-compatible surfaces. Their cold-marking capability ensures permanent high-contrast codes on delicate instruments while preventing material degradation that could violate FDA 21 CFR Part 11 requirements.

Aerospace Traceability: Fiber Laser Depth Control

Fiber lasers meet aerospace AS9100 standards through precise depth regulation in direct part marking (DPM). Their adjustable wavelength produces oxidation marks with controlled 0.001-0.5mm penetration on turbine blades, landing gear, and structural alloys.

Selection Guide: Matching Laser to Your Needs

The ideal laser system has to match the wavelength properties with the material characteristics. Fiber lasers are the most efficient option for metal marking needs—in part for aerospace traceability parts that necessitate deep, indelible characters. CO₂ systems perform exceptionally well with organics such as wood or glass where thermal vaporization will produce clean engravings. UV Lasers for Cold Marking and Fine Marking (includes UDI marking); cold micro-marking below 20 μm without substrate damage for UDI-compliant medical devices or sensitive electronics.

Evaluate three critical dimensions: material absorption spectra, regulatory requirements like FDA 21 CFR Part 11, and production volumes. Cross-reference thermal sensitivity against marking depth specifications to prevent deformation.

FAQ

What are the main differences between fiber, CO₂, and UV lasers?

Fiber lasers operate at 1064nm and are ideal for marking metals, while CO₂ lasers at 10.6μm are best for organics like wood and acrylic. UV lasers use 355nm photons for marking delicate materials without heat.

Which laser is best for marking organic materials?

CO₂ lasers are optimal for engraving organic materials, including wood, acrylic, and leather, due to their 10.6μm wavelength.

Can UV lasers be used for medical and electronic components?

Yes, UV lasers marking are effective for sensitive electronics and medical components due to their cold marking capabilities.