How Jewelry Laser Spot Welder Technology Transforms Precision Work

How Jewelry Laser Welding Machines Work

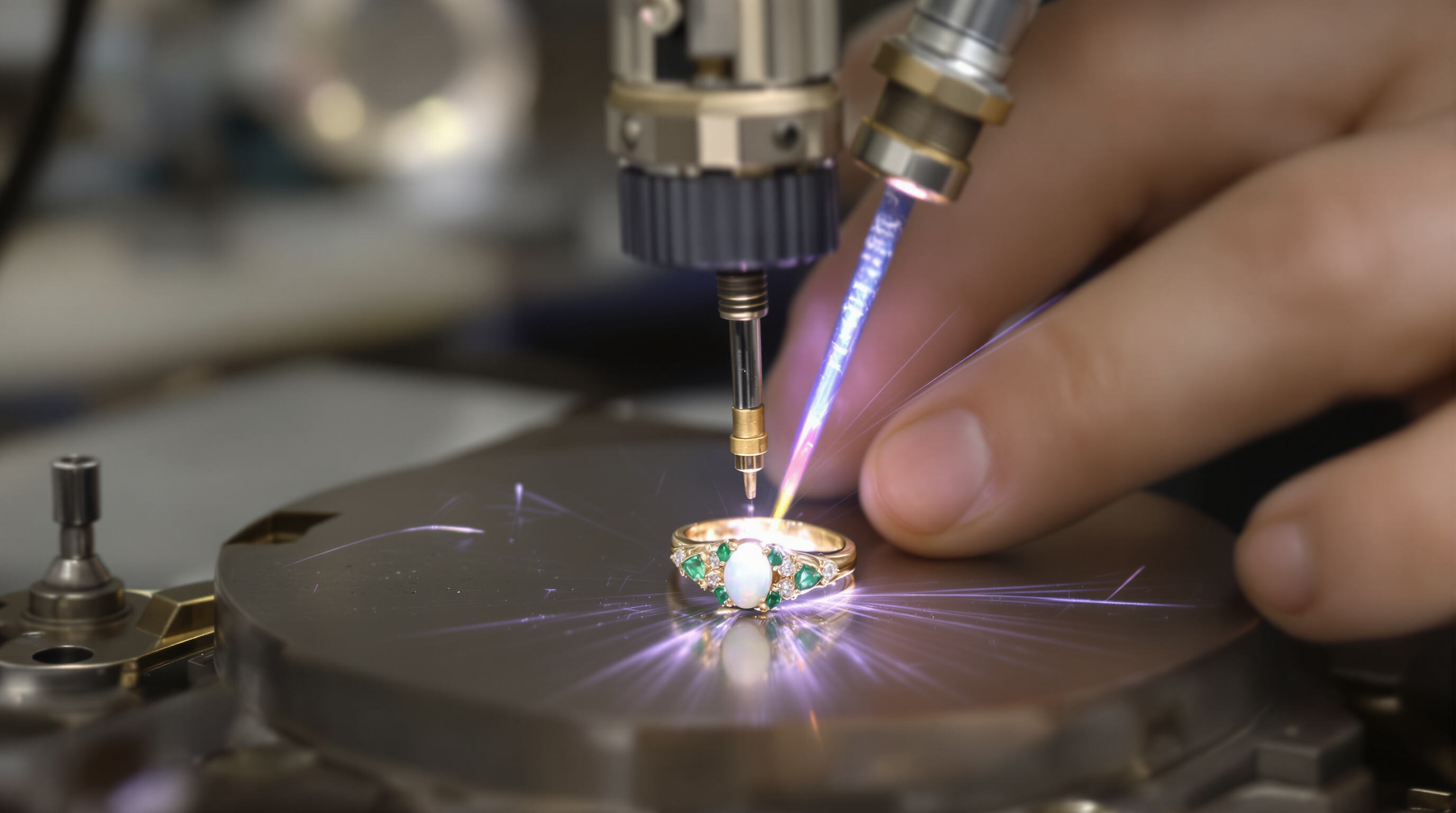

Today's jewelry laser spot welders rely on pulsed fiber lasers to produce those super focused energy beams. The spot size can range anywhere between 0.2 mm all the way up to 3.0 mm, which allows for really precise work down at the micron level. Traditional soldering methods heat up big chunks of metal at once, but these lasers are different. They zero in on just the right spots with power levels hitting between 5 and 12 kW. This means jewelers get those clean, seamless joins in precious metals without damaging surrounding gemstones or intricate designs. Some of the newer machines come with adjustable pulse settings that go from 0.1 milliseconds to 30 milliseconds, plus they have built-in temperature monitoring systems. These features make it possible to safely weld even the thinnest pieces of 24 karat gold, sometimes as delicate as 0.3 mm thick, without causing any unwanted warping or distortion.

Evolution From Traditional Soldering to Laser Precision in Jewelry Making

When jewelry studios started switching away from traditional torch soldering, things changed pretty fast once they saw repair requests fall by around 41% after getting laser systems according to the 2024 Jewelry Tech Report. Old school methods needed all that flux stuff and usually left those ugly little seams showing through. Laser welding basically gets rid of oxidation problems altogether while cutting down on the extra work needed afterward. Looking at numbers from a 2023 test, platinum chains made with lasers held up 32% better under tension compared to ones done the old way. That means stronger pieces that look nicer too, which explains why so many jewelers are making the switch these days.

Key Manufacturers Driving Innovation

Top manufacturers are starting to put AI assisted beam shaping along with dual wavelength technology inside their jewelry laser spot welders these days. This helps tackle problems that have plagued the industry for years, especially dealing with how reflective silver can be and those pesky thermal cracks that form in titanium alloys during welding. A company at the forefront of this innovation reported getting about 95 percent success rate right off the bat when joining different metals together. Think about something like attaching gold parts to stainless steel clasps. What used to seem impossible for complex hybrid designs is actually becoming quite feasible now thanks to these advancements in welding technology.

Tables are not used here since textual explanations better convey the technical nuances of laser parameters and material compatibility.

Unmatched Precision and Control in Delicate Jewelry Applications

Micro-Welding in Tight or Intricate Areas

Modern laser spot welders can get down to beam widths around 0.1 mm, which means they can fix stuff where regular tools just won't fit. This kind of fine control makes all the difference when someone needs to reinforce those delicate prong settings or mend tiny cracks in old jewelry. According to some research from the Goldsmiths Association back in 2023, these lasers hit a pretty impressive 92 percent success rate on their first try with complicated chain links. That number really speaks volumes about how dependable this tech has become for detailed repair work.

High-Precision Welding for Exceptional Detail

With pulsed energy delivery, craftsmen can create really clean seams that are anywhere from 0.05 to 0.3 mm wide something like the thickness of a single strand of hair. Such fine control makes all sorts of delicate work possible, including aligning tiny stones in pavé settings or restoring intricate micro-engravings without messing up nearby details. A recent survey of workshops throughout Europe found that these methods cut down on metal waste by around 40%. That means not only saving money for the shop owners but also preserving more material for future projects, which is good news for both the wallet and the art itself.

Consistency and Repeatability in Weld Quality

Automated power modulation ensures ±2% energy consistency during production runs, resulting in uniform weld penetration depths across mass-produced items like earring posts. Manufacturers report an 83% decrease in quality control rejections since implementing laser systems, reflecting significant improvements in output reliability.

Case Study: Achieving Sub-Millimeter Welds on Filigree Gold Designs

A collaboration between European conservators and laser engineers achieved 98% successful repairs on 19th-century filigree pieces using 0.08 mm welds. The process restored structural integrity while preserving original craftsmanship—a result unattainable with traditional soldering—and demonstrated the technology's potential for museum-grade restoration.

Minimal Heat Impact: Safeguarding Stones and Sensitive Materials

Focused Heat Input for Delicate Work

Laser spot welders used for jewelry work can produce beams as thin as 0.1 to 0.3 mm, which is actually finer than a strand of human hair. These devices generate about 85% less ambient heat compared to traditional torch methods, something recent metallurgy research from 2023 has confirmed. The level of control offered by these lasers makes all the difference when working near delicate gemstones. Thermal damage becomes a real concern with stones that are sensitive to heat, such as opals and emeralds, so this feature is pretty important for jewelers. When using pulsed laser settings, the actual exposure time during welding drops down to between 1 and 4 milliseconds. That short burst of energy reduces risks significantly without compromising the strength of the final bond, making it safer for both the materials and the craftspeople handling them.

Minimal Heat Distortion in Metal Joining

Regular soldering techniques actually warp gold alloys around three times more compared to laser welding according to standards set by the Goldsmiths Association. When jewelers focus heat intensity somewhere between 1.2 and 3.5 kilowatts per square millimeter right where they need it, they manage to keep those delicate molecular arrangements intact in intricate silver filigree work and platinum settings. This matters a lot for preserving both the worth and original condition of valuable antique jewelry and family heirlooms that have been passed down through generations.

Stone-Set Jewelry Repairs Without Stone Removal

A 2024 industry survey revealed that 78% of jewelers now repair bezel settings and pavé clusters without removing stones, thanks to adjustable wavelength lasers. This approach eliminates common issues associated with mechanical removal, including chipped gems (averaging $740 in repair costs), residue buildup from repeated heating, and labor-intensive resetting procedures.

Controversy Analysis: When Low Heat Compromises Joint Strength

Laser welding gets about 92% joint density when working with 14K gold according to a report from IJO in 2023, but there are still situations where controlling how heat spreads matters a lot. Take platinum alloys for example, they tend to have around 18 percent less tensile strength than what we see with traditional torch welding methods. The jewelry industry has started developing these mixed approaches lately. What happens is welders will first do some precise laser tacking work, then follow it up with micro soldering on those really important structural parts. This combination seems to strike that sweet spot between making sure things stay safe and maintaining adequate strength throughout the piece.

Expanding Applications: From Ring Resizing to Custom Design Innovation

Laser spot welders for jewelry are changing how jewelers work, making it possible to do really precise repairs and open up new design ideas. These machines control the heat so well that rings can be resized within about 0.15 mm without getting too hot. The temperature stays under 120 degrees Celsius according to what most shops follow these days. This means no warping happens to those expensive platinum or gold rings. Plus, there's no need to take out delicate stones during the process, which saves time and reduces risk for both the jeweler and customer.

Non-Invasive Adjustments to Platinum and Gold Bands

Focused laser beams target exact weld zones without affecting surrounding areas, making it feasible to modify heirloom pieces or thin-walled designs previously too delicate for alteration.

Real-World Example: 30% Faster Turnaround in Custom Ring Modifications

An industry analysis found that workshops using laser welding reduced average ring resizing time from three days to five hours, leveraging non-contact joining and automated parameter presets for rapid, repeatable results.

Pushing Boundaries in Avant-Garde Jewelry Design

Leading manufacturers now pair laser welders with 3D modeling software to create organic, free-form structures:

| Design Feature | Manual Technique Limitation | Laser Welding Advantage |

|---|---|---|

| Microscopic interlocking | ¥1mm joint gaps | 0.2µm weld precision |

| Hollow geometric forms | Solder pooling risks | No filler material contamination |

| Mixed-metal topologies | Thermal expansion mismatch | Sequential pulse programming |

This technological leap has driven a 47% increase in bespoke orders since 2022, as designers use laser systems to realize client visions—from algorithmically generated patterns to metamaterial-inspired textures—proving that laser welding doesn't just improve efficiency but enables entirely new categories of wearable art.

Material Versatility and Future Integration in Jewelry Production

Welding of Gold and Silver Jewelry With Consistent Results

Jewelry makers who use modern laser spot welders find they get reliable results when working with different types of gold from 10K all the way up to 24K, plus various silver alloys like sterling and fine silver too. Traditional torch techniques often lead to hot spots and cold areas, but those pesky problems disappear with lasers that create butt joints having under 3% porosity as studies have shown. The best equipment can make welds just 0.1 mm wide on delicate 22K gold chains, something that matters a lot when restoring valuable pieces where maintaining the original karat content is absolutely essential for both authenticity and market value.

Challenges and Solutions in Platinum Laser Welding

Platinum’s high melting point (1,768°C) and rapid heat dissipation historically caused warping and cracking. Advanced systems now overcome these issues through multi-axis pulse modulation (up to 2,000 Hz), reactive gas shielding (95% argon/5% hydrogen), and real-time thermal imaging to prevent grain boundary defects.

Data Point: 95% Success Rate Across Dissimilar Metal Joins

A 2024 materials science study demonstrated 95% joint integrity in gold-to-platinum connections using laser welding—a 40% improvement over conventional techniques. This breakthrough enables durable mixed-metal designs, such as titanium clasps on heritage gold lockets, without compromising structural reliability.

Future Outlook: Integration With CAD/CAM and Automation Systems

Workshops on the cutting edge are now combining laser welders with 3D scanners that figure out the best welding routes for unique designs. Jewelers who've tried these systems say they can develop prototypes for complicated shapes about 70% quicker than before. They also save around half the materials because the AI places joints where they make the most sense. What's really impressive is how smoothly these digital blueprints translate into actual products sitting on display cases. The blending of computer modeling with such precise manufacturing techniques makes laser welding stand out as a key part of what's called Industry 4.0 in the jewelry world. This matters a lot for sustainability too, since many jewelers are finding ways to take old family treasures and turn them into modern fashion statements without wasting precious metals.

FAQ

What is the advantage of using laser welders over traditional soldering in jewelry making?

Laser welders allow for precise and seamless joining of metals without damaging gemstones or intricate designs. They significantly reduce repair requests and improve the structural integrity of pieces compared to traditional soldering.

How do laser welding machines maintain precision in delicate jewelry work?

These machines use focused laser beams with adjustable pulse settings and temperature monitoring systems, enabling safe welding of even the thinnest pieces without warping or distortion.

Can laser welding be used for all types of metals in jewelry?

Yes, modern laser spot welders are versatile and can reliably work with various gold karats and silver alloys. They also accommodate mixed-metal designs, such as gold-to-platinum connections, with high success rates.

Does laser welding affect the gemstones in jewelry?

No, laser welding produces minimal heat, safeguarding sensitive gemstones from thermal damage, making it safer for both materials and jeweler.

What is the future of laser welding technology in jewelry production?

The future involves integrating laser systems with CAD/CAM and automation, improving design precision, reducing material waste, and enabling innovative custom designs.

Table of Contents

- How Jewelry Laser Spot Welder Technology Transforms Precision Work

- Unmatched Precision and Control in Delicate Jewelry Applications

- Minimal Heat Impact: Safeguarding Stones and Sensitive Materials

- Expanding Applications: From Ring Resizing to Custom Design Innovation

- Material Versatility and Future Integration in Jewelry Production

-

FAQ

- What is the advantage of using laser welders over traditional soldering in jewelry making?

- How do laser welding machines maintain precision in delicate jewelry work?

- Can laser welding be used for all types of metals in jewelry?

- Does laser welding affect the gemstones in jewelry?

- What is the future of laser welding technology in jewelry production?