How Laser Metal Cleaning Machines Work: Precision Through Non-Contact Technology

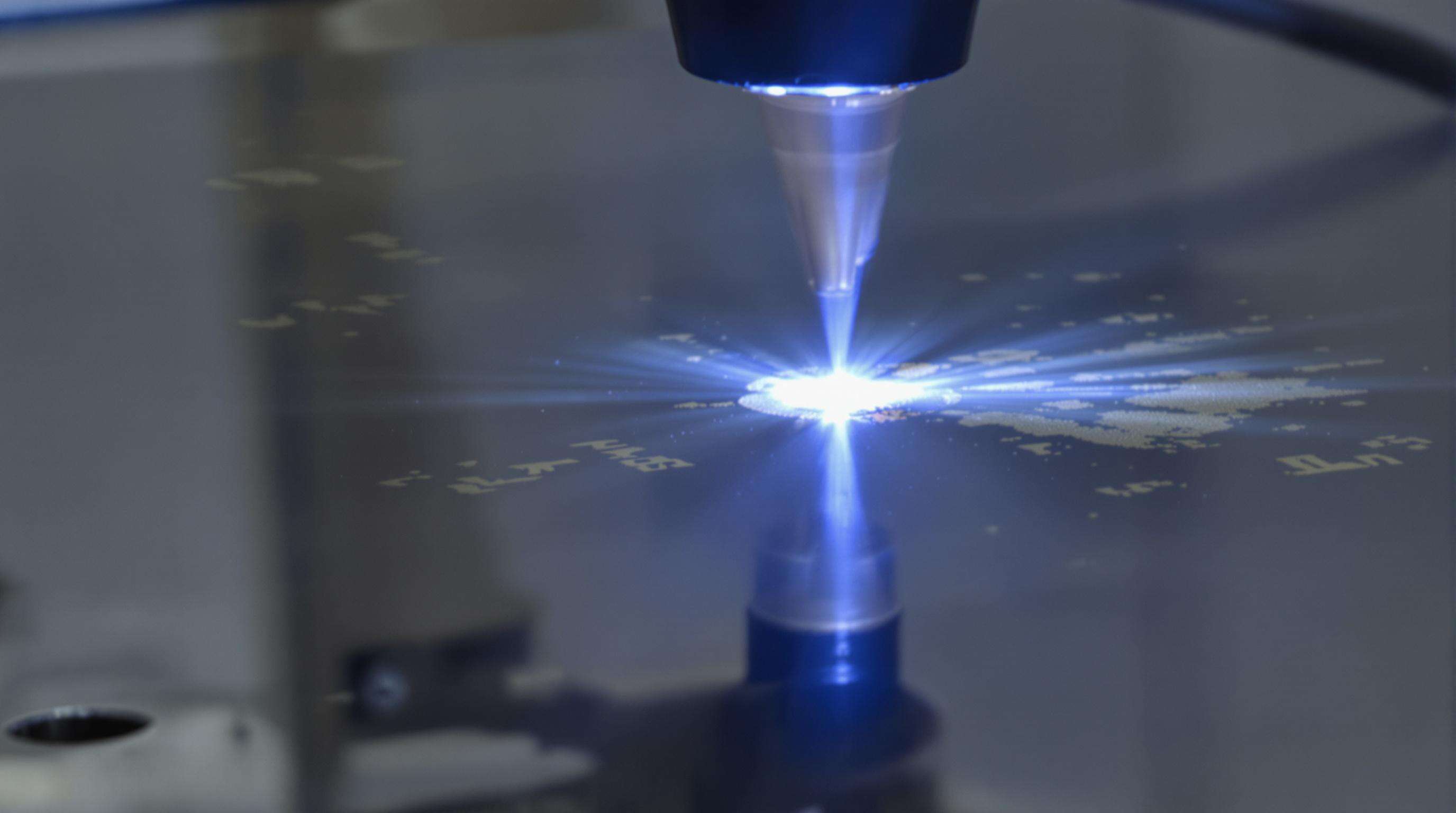

Laser metal cleaning machines remove contaminants using controlled energy delivery without physical contact. By focusing laser beams on microscopic impurities, these systems vaporize layers of contamination while preserving the integrity of delicate substrates.

The Science of Ablation Thresholds and Selective Material Removal

Materials all have their own specific point where lasers start breaking those molecular bonds, what we call the ablation threshold. Smart laser systems take advantage of how these thresholds differ between things like rust and oxidation versus actual base metals. Take copper alloys for instance. The oxidized layer can soak up about 150 percent more energy compared to clean surfaces, which lets technicians strip away corrosion while keeping the good metal underneath intact. Contemporary laser control software keeps changing the power density measured in joules per square centimeter so it doesn't cross into dangerous territory when working with delicate materials. This kind of fine tuning makes a big difference in industrial settings where material integrity is absolutely crucial.

Pulsed vs. Continuous-Wave Lasers: Why Solid-State Lasers Enhance Control on Sensitive Surfaces

For delicate work, many professionals turn to pulsed solid state lasers because they produce these really short bursts of energy lasting somewhere between a millionth and a billionth of a second. These quick flashes cut down on heat buildup by around two thirds when compared with those continuous wave systems that run all the time. The way these lasers work gives materials time to cool between each pulse, making it possible to control exactly how deep the material gets removed down to tiny fractions of a millimeter. Take electronics manufacturing as an example where 50 watt pulsed lasers do a great job cleaning away oxide layers on those thin copper circuits measuring just 0.2 mm thick. And best of all, temperatures stay below 15 degrees Celsius during this process so there's no risk of warping those complex multi layer printed circuit boards.

Non-Abrasive Cleaning Advantages for Delicate Metals and Coated Substrates

| Cleaning Method | Surface Abrasion Risk | Residual Stress | Post-Cleaning Finish |

|---|---|---|---|

| Laser Cleaning | None | <50 MPa | Mirror-polished |

| Sandblasting | High | 200–300 MPa | Matte texture |

This non-contact method prevents micro-scratches on soft metals like aluminum (HV 15–25) and maintains adhesion-ready surfaces for coated materials. Aircraft manufacturers report 98% coating retention rates with laser cleaning, compared to 73% using mechanical methods on titanium engine components.

Evaluating Safety: Preventing Thermal and Structural Damage to Sensitive Materials

Risks of Warping, Discoloration, and Micro-Damage on Thin Metals During Laser Cleaning

Laser cleaning works really well for most applications, but getting the settings wrong can lead to serious problems down the road. When working with thin aluminum sheets between 0.5 and 2 mm thick, there's actually around 12 to 25 percent greater chance of warping happening if we use continuous lasers above 150 watts power level. Some recent research published last year in Applied Surface Science showed something interesting though - switching to pulsed laser technology cuts down on heat buildup by roughly 40 to 60 percent, which helps keep those pesky color changes at bay when dealing with copper based materials. And watch out for nickel superalloys too because these special metals tend to develop tiny cracks measuring less than 5 micrometers deep whenever the laser pulses last longer than 15 nanoseconds. That kind of microscopic damage might not seem bad at first glance, but it definitely affects long term performance and reliability.

Optimizing Power Settings and Pulse Duration to Protect Delicate Surfaces

Safe material removal depends on balancing key parameters:

| Parameter | Safe Range for Thin Metals | Effect on Surface Integrity |

|---|---|---|

| Peak Power Density | 0.8–1.5 GW/cm² | Prevents melt-phase ablation |

| Pulse Duration | 10–100 ns | Limits thermal penetration |

| Repetition Rate | 20–50 kHz | Maintains cooling intervals |

| Reducing power by 30% from manufacturer defaults decreases thermal stress in titanium aerospace components by 52%, while maintaining 90% cleaning efficacy. |

Using Low- and Medium-Power Lasers for Precision Without Compromising Substrate Integrity

Fiber lasers in the low power range (around 20 to 50 watts) can selectively remove oxides from bronze artifacts without harming the delicate historical patina layers that might be just 3 micrometers thick. When it comes to medium power systems between 75 and 120 watts, these tools offer impressive precision for cleaning circuit boards. They manage to strip away material down to about 0.02 millimeters, which is roughly comparable to removing coating from 30 AWG wire without touching the insulation underneath. What makes these systems really stand out is their real time thermal monitoring feature. As surfaces start getting close to that important 60 degree Celsius mark where polymer coatings on steel begin to break down, the system smartly reduces power output to prevent damage.

Applications on Delicate Metals: Balancing Effectiveness and Safety

Cleaning Aluminum, Copper, and Titanium Without Damaging Base Material

Laser cleaning works really well at getting rid of oxidation layers without messing up the strength of lightweight metals. When it comes to those special aerospace aluminum alloys, we find that pulsed lasers around 25 watts or lower do the job just right. They clean away all sorts of dirt and grime without changing how resistant these materials are to corrosion. The electronics industry has also jumped on board with this technology. Solid state lasers that fire pulses shorter than 10 billionths of a second can clear oxides off thin copper layers about a tenth of a millimeter thick without causing tiny cracks. And for medical applications, titanium surgical implants get treated with fiber lasers operating at about 1,070 nanometers wavelength. These lasers effectively strip away organic stuff left behind during manufacturing while keeping the implant safe for human bodies.

Case Study: Removing Oxides From Thin Copper Circuits in Electronics Manufacturing

A 2023 industrial trial showed a 50W pulsed laser removed copper oxide (CuO) from PCBs with 98% efficiency. With 40% beam overlap and 3.5 J/cm² fluence, substrate temperature rose by â¤8°Câpreventing warping in multi-layer boards. This non-abrasive method eliminated toxic waste from chemical etching and reduced cleaning cycle times by 73%.

Limitations of Laser Cleaning on Ultra-Thin Coatings and Heat-Sensitive Alloys

Laser systems require careful tuning for materials under 50µm thickness. Nickel-aluminum thermal barrier coatings risk delamination above 400°C, requiring pulse frequencies below 20kHz. Zinc-nickel electroplated surfaces on automotive parts need sub-millisecond pulses to prevent zinc depletion, a common failure in high-throughput settings.

Non-Destructive Cleaning in Heritage Conservation

Laser Cleaning of Cultural Artifacts: Preserving Patina While Removing Corrosion

Laser cleaning selectively removes corrosion while preserving irreplaceable patina on cultural artifacts. Pulsed solid-state lasers target contaminants at ablation thresholds of 0.5–2.5 J/cm² for bronze and iron, avoiding substrate alteration. A 2022 analysis of medieval iron relics showed 98% corrosion removal with less than 0.003 mm material loss, maintaining historical oxidation patterns.

Case Study: Restoring Ancient Bronze Artifacts With Minimal Surface Impact

A 50-W fiber laser restored 15th-century Ming Dynasty bronze statues using 80 kHz pulse frequency and 80 ns pulse duration, resulting in:

| Metric | Pre-Cleaning | Post-Cleaning | Improvement |

|---|---|---|---|

| Surface roughness (Ra) | 12.7 µm | 3.2 µm | 75% reduction |

| Chloride concentration | 6,800 ppm | 290 ppm | 95% removal |

| Patina thickness | 180 µm | 175 µm | <3% change |

This process removed 400 years of contamination while preserving the original protective patina.

The Precision Paradox: Achieving Clean Surfaces Without Irreversible Damage

According to research published by ICOMOS-CCROM in 2023, there remains a significant problem when trying to eliminate damaging substances like chlorides that actually speed up bronze disease development while avoiding any photothermal harm. Today's technology tackles these issues through several approaches including constant temperature checks that keep things below 80 degrees Celsius, fine tuning light wavelengths between around 1,030 to 1,070 nanometers, and adjusting laser pulses as needed during treatment. These new techniques make it possible to clean delicate materials even something as thin as 0.2 millimeter gold leaf without losing more than about 0.1 percent of the original material which simply wasn't feasible using older conventional methods.

Laser Safety Standards and Operational Precautions for Sensitive Environments

Laser metal cleaning machines require strict adherence to Class I–IV safety classifications and customized protocols, especially for delicate surfaces. Industrial cleaning typically uses Class 4 lasers (high-power, pulsed solid-state systems), which demand engineered safeguards to prevent thermal distortion or unintended ablation.

Understanding Laser Classifications (Class I–IV) and Their Relevance to Delicate Surface Cleaning

Class 4 lasers (500 mW–10 kW) pose risks such as unintended material removal or beam scattering. Safety standards like IEC 60825-1 and ANSI Z136.1 (2023) require beam enclosures, fume extraction, and oversight by a laser safety officer (LSO), particularly when working with heat-sensitive alloys or coatings under 50 ¼m.

Essential Safety Measures for Protecting Operators and Materials During Laser Cleaning

Critical precautions include:

- Wavelength-specific eyewear with ODâ¥7 optical density to block 1,064 nm fiber laser reflections

- Real-time thermal monitoring limiting substrate temperatures to <120°C for aluminum or <80°C for polymer coatings

- Isolation tables with vibration dampeners to maintain <5 ¼m precision on curved surfaces

Integrating Safety Protocols Into Non-Invasive Cleaning Workflows

Modern systems embed safety into operational sequencesâinterlocks halt processing if enclosures open, and AI-powered vision systems adjust power upon detecting surface irregularities. This integration reduces human error by 72% compared to manual override systems (Laser Processing Journal, 2023), a vital improvement for restoring historical artifacts and aerospace components.

FAQs on Laser Metal Cleaning Machines

What are laser metal cleaning machines used for?

Laser metal cleaning machines are used to remove contaminants from metal surfaces without physical contact, achieving precision in cleaning by using a controlled laser beam to vaporize impurities.

How do pulsed lasers differ from continuous-wave lasers?

Pulsed lasers emit short bursts of energy, reducing heat buildup, which is beneficial for delicate surface cleaning, while continuous-wave lasers constantly emit energy, potentially increasing heat stress.

Why is laser cleaning preferred for delicate metals and coatings?

Laser cleaning is non-abrasive, preserving the base metal and coatings without causing surface scratches, making it ideal for sensitive materials.

What safety precautions are essential when using laser cleaning machines?

Key safety measures include using wavelength-specific protective eyewear, real-time thermal monitoring, isolation tables, and ensuring adherence to laser safety classifications and standards.

How does laser cleaning benefit heritage conservation efforts?

Laser cleaning allows conservators to remove corrosion without damaging the patina or original substrate of cultural artifacts, preserving historical integrity.

Table of Contents

- How Laser Metal Cleaning Machines Work: Precision Through Non-Contact Technology

- Evaluating Safety: Preventing Thermal and Structural Damage to Sensitive Materials

- Applications on Delicate Metals: Balancing Effectiveness and Safety

- Non-Destructive Cleaning in Heritage Conservation

- Laser Safety Standards and Operational Precautions for Sensitive Environments

-

FAQs on Laser Metal Cleaning Machines

- What are laser metal cleaning machines used for?

- How do pulsed lasers differ from continuous-wave lasers?

- Why is laser cleaning preferred for delicate metals and coatings?

- What safety precautions are essential when using laser cleaning machines?

- How does laser cleaning benefit heritage conservation efforts?