Why Aluminum and Copper Challenge Standard Fiber Laser Marker Settings

High reflectivity and thermal conductivity: Physics-based barriers to consistent marking

Working with aluminum and copper presents real challenges for standard fiber laser markers because of two basic physical traits they share. First, both materials have very high near infrared reflectivity rates - around 90% for copper and between 65% to 95% for different aluminum alloys depending on how clean the surface is. Second, their thermal conductivity is exceptional, reaching up to 400 W/mK for pure copper and about 200-250 W/mK for typical aluminum alloys. These characteristics mean most laser energy just bounces away instead of being absorbed, and whatever does get absorbed quickly spreads out across the material. This makes it hard to create those clear, repeatable marks we need since there's not enough localized melting or color change happening. Standard settings usually lead to frustrating compromises where low power gives barely visible markings but high power causes all sorts of unwanted thermal damage. That's why working with these non ferrous metals requires completely different approaches compared to steel or titanium, ones that take into account exactly how light interacts with them and how fast heat moves through their structures.

Common failure modes: Burn marks, shallow contrast, and surface oxidation in reflective metals

Without parameter optimization, standard fiber laser markers produce three recurring failures on aluminum and copper:

- Thermal runaway, where inconsistent absorption leads to localized overheating, carbonization, and burned edges;

- Low-contrast or shallow marks, failing automated vision inspection and industrial readability standards like ISO/IEC 15415;

- Uncontrolled surface oxidation, especially problematic on anodized aluminum where discoloration violates aesthetic or functional specifications.

These issues stem directly from mismatched pulse energy, duration, and beam geometry—not operator error—and routinely cause part rejection and production downtime in high-volume manufacturing.

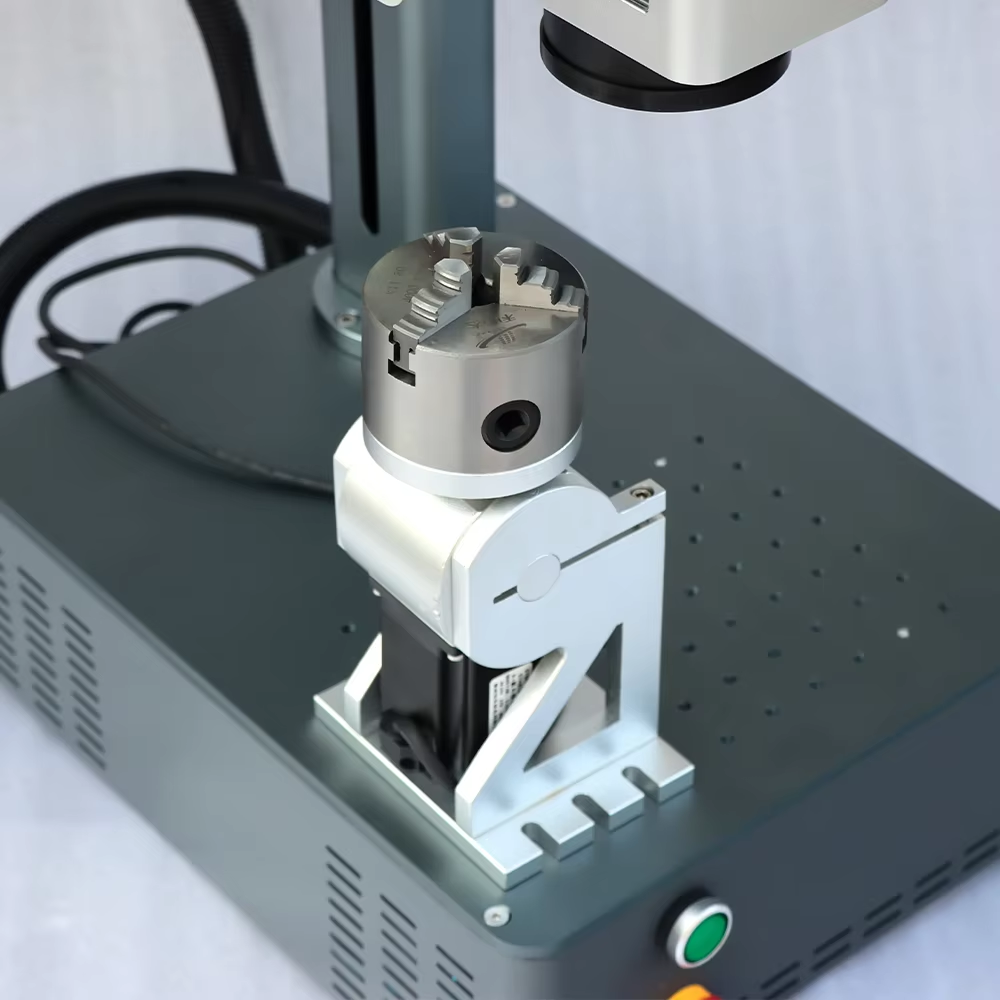

Optimizing Fiber Laser Marker Parameters for Reliable Aluminum and Copper Marking

Critical settings: Pulse duration, peak power, frequency, and focal offset for reflective metals

Reliable marking requires precise, interdependent tuning of four core parameters:

- Pulse duration: ‰100 ns pulses confine energy before thermal diffusion occurs, minimizing burn risk and preserving surface integrity;

- Peak power: ‰¥80 kW intensities overcome initial reflectivity to initiate controlled surface interaction—critical for visible contrast without ablation;

- Frequency: 20–50 kHz repetition rates balance mark speed with sufficient inter-pulse cooling, preventing cumulative heat buildup;

- Focal offset: Defocusing by 0.5–2 mm widens the beam spot, lowering power density to suppress oxidation while maintaining enough fluence for consistent marking.

These adjustments respond directly to the materials’ optical and thermal profiles—notably copper’s 65%+ reflectivity at 1064 nm and aluminum’s rapid heat dissipation—and must be validated per alloy grade (e.g., 6061 vs. 7075 aluminum) and surface condition (mill finish, anodized, coated).

MOBA vs. CW fiber laser marker sources: When pulsed operation prevents reflection damage

When it comes to working with reflective metals, MOPA (Master Oscillator Power Amplifier) fiber lasers beat continuous-wave (CW) systems hands down. The problem with CW lasers is they keep putting out energy all the time, which creates serious issues with back reflections that can mess up optics and throw off the whole system. MOPA lasers work differently though. They fire these short bursts of really powerful energy at just the right moments, getting into the material before reflections become a problem. According to several industrial safety reports, this approach cuts down on reflection problems by about three quarters. And when dealing specifically with copper, the way MOPA controls its pulses makes grayscale marking possible. Instead of actually removing material like traditional methods do, it creates those nice high contrast marks by forming controlled oxide layers on the surface. This means better quality marks without wearing away the metal itself.

Advanced Techniques to Enhance Fiber Laser Marker Performance on Reflective Metals

Surface pre-treatment (anodizing, coating) and post-process passivation strategies

The right pre-treatment makes all the difference when dealing with reflective metals. Anodizing aluminum creates a special porous layer that actually soaks up light instead of bouncing it back. This can boost how well lasers work with the metal by around 70% in many cases, which means we get better marks without needing such intense power levels. For other metals like copper, temporary coatings made from ceramics or polymers do basically the same job during marking processes. They cut down on reflection while the marking happens and then wash away completely after the job is done. What comes next matters too. After marking, proper passivation is critical. Different chemicals are used depending on what metal we're working with. Aluminum typically gets treated with something like chromate or trivalent chromium solutions, while copper often needs benzotriazole. These treatments form protective barriers that stop problems like white rust forming on aluminum or tarnishing on copper surfaces, especially important where there's moisture or salt in the air. All these steps together keep markings clear to read, strong enough to last, and meet those strict standards required in industries ranging from aerospace components to medical devices and electronic parts.

Real-time beam monitoring and adaptive feedback systems for stable fiber laser marker output

Variations in materials - think things like slight oxidation on surfaces, leftover oils, or uneven distribution of alloys - lead to changes in how much light gets reflected versus absorbed during marking processes. Modern fiber laser markers now come equipped with built-in optical sensors that keep track of several key parameters including beam strength, where the focus lands, and how strong the returning signal is, all happening at speeds around 10,000 times per second. These closed loop systems take that information and tweak settings on the fly, adjusting things like pulse energy levels, maximum power output, and even the focal point's position within fractions of a second. Let's say there's a spike in reflected energy detected because the material suddenly becomes more reflective; the system responds by cranking up the pulse intensity just enough to keep those marks looking uniform and clear. Real world tests across auto manufacturing plants and electronic component factories indicate these smart systems can slash waste products by about 40 percent. Plus they help meet all those important tracking standards companies need to follow, stuff like UDI codes for medical devices or AS9132 requirements in aerospace manufacturing.

FAQ

Why do aluminum and copper require different laser settings compared to steel?

Aluminum and copper have high reflectivity and thermal conductivity, causing most laser energy to bounce away or dissipate quickly, making marking challenging compared to steel.

What are some common issues when marking aluminum and copper with lasers?

Without proper settings, lasers can cause thermal runaway, low-contrast marks, and uncontrolled surface oxidation on aluminum and copper.

How can I optimize fiber laser settings for aluminum and copper?

By adjusting pulse duration, peak power, frequency, and focal offset, tailored to the specific alloy and surface conditions.

How do MOPA lasers benefit marking reflective metals?

MOPA lasers prevent reflection damage by delivering short, intense energy bursts, allowing for controlled surface interaction.

What role does pre-treatment play in laser marking reflective metals?

Pre-treatments like anodizing or temporary coatings reduce reflection and enhance mark quality by increasing laser absorption.

Table of Contents

- Why Aluminum and Copper Challenge Standard Fiber Laser Marker Settings

- Optimizing Fiber Laser Marker Parameters for Reliable Aluminum and Copper Marking

- Advanced Techniques to Enhance Fiber Laser Marker Performance on Reflective Metals

-

FAQ

- Why do aluminum and copper require different laser settings compared to steel?

- What are some common issues when marking aluminum and copper with lasers?

- How can I optimize fiber laser settings for aluminum and copper?

- How do MOPA lasers benefit marking reflective metals?

- What role does pre-treatment play in laser marking reflective metals?