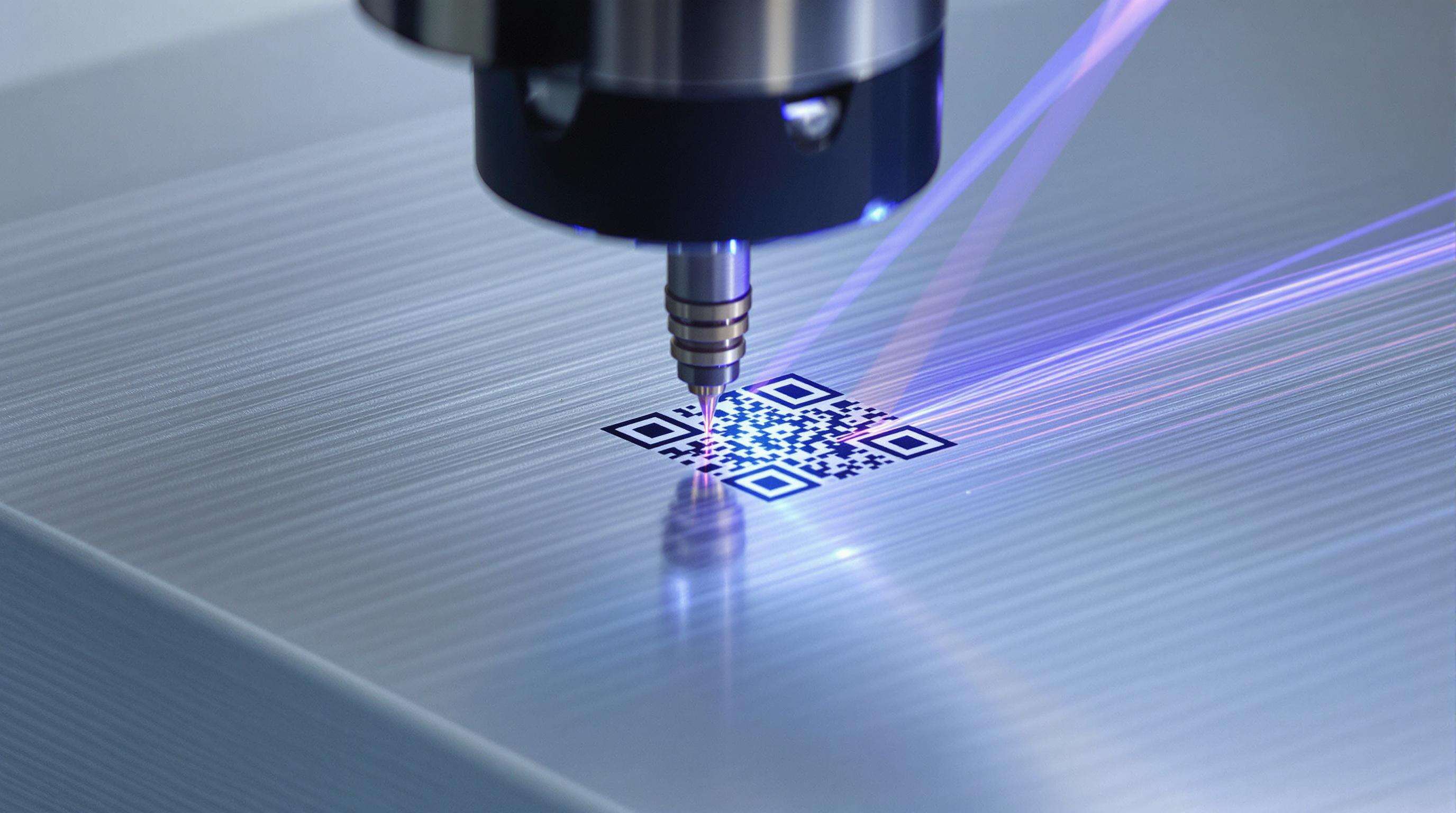

Superior Precision and Micron-Level Accuracy

Fiber laser marking machines achieve micron-level precision through focused beam diameters as small as 20µm and advanced galvo scanning systems. This enables crisp 2D codes, fonts under 0.1mm, and intricate logos on metals, ceramics, and polymers—without warping—making it essential for aerospace component serialization and medical implant traceability.

How Fiber Laser Marking Achieves Micron-Level Precision

Precision stems from three core technologies:

- Beam quality (M² ≤1.1) minimizes focal spot dispersion

- High-frequency pulsed lasers (100–300kHz) allow micro-impact engraving

- Closed-loop galvo scanners maintain ±5µm positional accuracy across 200mm work areas

According to a 2023 IACS report, fiber lasers produce features three times smaller than CO₂ lasers on titanium alloys, with 15µm repeatability compared to 50µm for conventional methods.

The Role of Beam Quality in Precision and Traceability

A near-perfect TEM00 beam profile ensures uniform energy distribution across microscopic zones, enabling:

- Legible QR codes in areas under 0.5mm²

- Permanent UID marks on surgical tools that endure 500+ autoclave cycles

- Less than 0.25% read errors in automotive VIN marking

Aerospace manufacturers now require M² ≤1.3 lasers for FAA-compliant tracking, with beam analysis reports included in quality documentation.

Case Study: High-Precision Marking in Aerospace Manufacturing

A tier-1 jet engine supplier reduced scrap rates by 63% after switching to fiber laser marking for turbine blade serialization. The system achieved:

- 25µm alphanumeric legibility on Inconel 718

- 0.003mm depth consistency across curved surfaces

- 98% first-pass readability, up from 82% with dot-peen markers

Trend: Rising Demand for Accuracy in Medical Device Marking

Medical OEMs now specify ≥50µm marking tolerances to comply with FDA UDI regulations. A 2024 Emergen Research study projects 29% CAGR in dental implant laser marking systems, driven by demand for:

- Sub-surface annealing marks in cobalt-chrome alloys

- Non-contact marking of polymer catheter surfaces

- Bio-compatible oxide layer modifications on titanium screws

High Speed and Industrial Efficiency

Accelerated Production Cycles With Fiber Laser Speed

Fiber lasers exceed 25,000 marks per hour thanks to optimized beam delivery, reducing cycle times by 32% compared to traditional methods (International Automotive Manufacturers Association 2023). Instantaneous power modulation eliminates warm-up delays common in CO₂ systems, enabling continuous high-speed operation.

High Peak Power and Pulse Rates Boosting Engraving Speed

Modern fiber lasers deliver up to 50 kW peak power and pulse frequencies of 1 MHz, engraving hardened steel 40% faster than legacy technologies. Customizable pulse durations (5–200 ns) maintain precision at industrial speeds, achieving 0.05 mm/s positioning accuracy even at maximum travel velocity.

Case Study: 50% Faster Serialization in Automotive Manufacturing

A Tier 1 auto parts supplier reduced VIN plate marking time from 8.2 to 4.1 seconds per unit after implementing fiber laser systems. A 14-month review revealed:

| Metric | Improvement | Source |

|---|---|---|

| Daily throughput | +89% | Internal Manufacturing Report 2024 |

| Energy cost/part | -62% | American Society of Mechanical Engineers |

| Defect rate | 0.003% | ISO 9001 Audit Findings |

The upgrade eliminated production bottlenecks while maintaining GS1 barcode compliance.

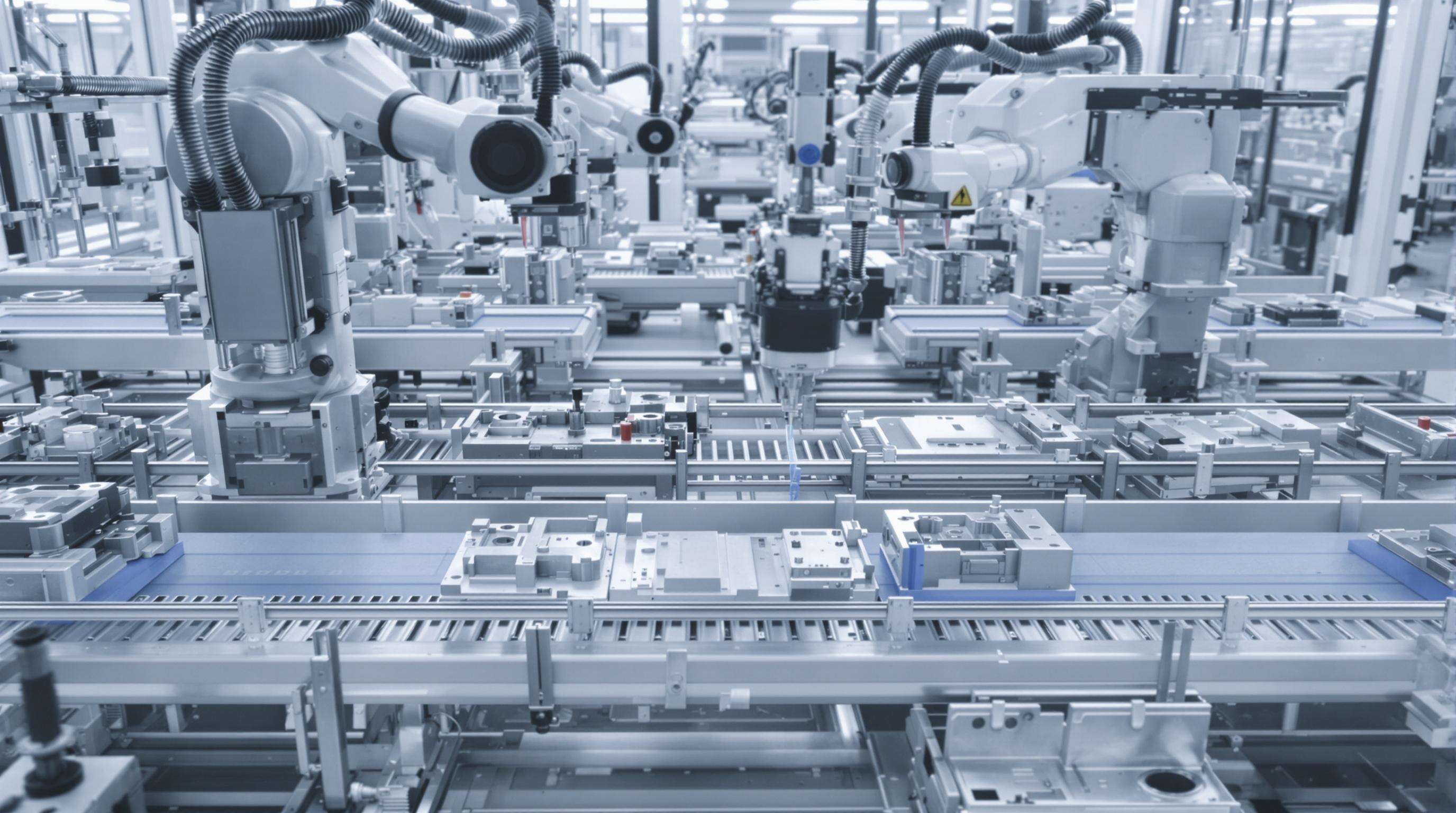

Integration With Automated Production Lines for Real-Time Marking

Leading manufacturers integrate fiber lasers with robotic arms and vision systems for adaptive, real-time marking. This enables:

- Instant design updates via MES software

- Sub-second product recognition and parameter adjustment

- Synchronization with conveyors moving at 12 m/s

These capabilities support just-in-time production and reduce work-in-process inventory by 18–22% across surveyed assembly plants.

Energy Efficiency and Environmental Sustainability

Lower power consumption vs. CO2 and YAG lasers

Fiber laser systems consume 30–50% less energy than CO₂ and lamp-pumped YAG lasers, according to industry benchmarks. Their solid-state design eliminates energy-intensive components like gas chambers and cooling systems, reducing idle power draw by up to 70%—a significant advantage for multi-unit, multi-shift operations.

Diode-pumped design enables energy-efficient laser fiber marking

The diode-pumped architecture converts 80% of input energy into usable laser light, far exceeding the 15–20% efficiency of conventional systems. This reduces operational costs by $3,800 annually per machine (based on 24/5 operation) and supports maintenance-free performance, further enhancing long-term savings.

Case Study: Energy savings in 24/7 electronics manufacturing

One large PCB manufacturing plant managed to slash their energy consumption by around 40% when they swapped out those old CO2 lasers for newer fiber optic versions. The switch saved them approximately 1.2 gigawatt hours each year, which adds up pretty quickly. When they started tracking usage in real time, they found that most of the power draw happened while actually doing the marking work on the boards. This turned out to be about three times better than what their previous setup could manage. These kinds of improvements match exactly what experts suggested back in the latest Industrial Laser Sustainability Report from 2024 regarding ways to cut down on wasted energy during ongoing manufacturing processes.

Growing adoption in green manufacturing initiatives

Over 58% of manufacturers now prioritize energy-efficient fiber laser marking in ESG strategies, especially in automotive and medical sectors. Government incentives like the Clean Production Tax Credit (CPTC) are accelerating adoption, with facilities achieving ISO 50001 certification 30% faster when using fiber lasers.

Cost-Effectiveness and Long-Term ROI

Fiber laser marking systems reduce total ownership costs while increasing output. Operational expenses drop 30–50% over five years compared to inkjet or chemical etching, driven by lower energy use and minimal consumables.

Declining Total Cost of Ownership Over Lifespan

The diode-pumped design eliminates gas refills and filament replacements, cutting annual maintenance costs by 60–70% after the first year. A 2023 Laser Systems Audit found that facilities using 100W fiber lasers saved $18,000 in energy costs over three years versus CO₂ systems.

Low Consumables and Energy Use Drive Cost Efficiency

With no inks, solvents, or masks required, manufacturers save $0.03–$0.15 per marked part. The table below compares legacy and fiber laser costs:

| Cost Factor | Inkjet Marking | Fiber Laser Marking |

|---|---|---|

| Annual Consumables | $24,000 | $0 |

| Energy per Hour | $3.80 | $0.90 |

| Maintenance/Year | $8,500 | $1,200 |

Case Study: ROI in a Mid-Sized Metal Fabrication Shop

A Wisconsin-based manufacturer achieved full ROI in 14 months—32% faster than projected—after switching to fiber laser marking. The system’s 85% energy efficiency reduced monthly power bills by $1,200 and increased throughput by 220%.

Upfront Cost vs. Long-Term Savings: Resolving the Debate

Although fiber lasers require a 20–35% higher initial investment than inkjet systems, break-even typically occurs within 18–24 months. For high-volume producers, lifetime savings often exceed $200,000 per machine through:

- 90% reduction in consumable purchases

- 50% lower preventive maintenance costs

- 40% faster cycle times enabling higher order volumes

Strategy: Calculating Break-Even for Inkjet to Fiber Laser Transition

Use this formula to assess transition feasibility:

Break-Even Months = (Fiber Laser Cost - Inkjet Resale Value) ÷ (Monthly Savings from Consumables + Energy + Labor) Most facilities achieve payback within 20 months when monthly production exceeds 15,000 units, with ROI compounding annually as legacy system costs rise.

Non-Contact Marking for Sensitive and High-Purity Applications

Eliminating Mechanical Wear and Material Deformation

Fiber laser marking is non-contact, preventing scratches or structural damage common in mechanical engraving. A 2023 materials science study found non-contact methods reduce deformation risks by 92% when marking thin aerospace alloys and medical-grade polymers—critical for components requiring micrometer-level tolerances.

Advantages in Fragile or Contamination-Sensitive Environments

This method doesn't produce any particulate matter at all, which makes it perfect for those super clean spaces like cleanrooms and other sterile areas. Labs working on pharmaceutical products have started using this technique to label their glass vials without introducing any contaminants into sensitive samples. Semiconductor companies are also getting on board, needing this kind of marking system for serializing wafers in facilities that must maintain ISO Class 1 standards. According to recent industry reports, around 78 percent of microelectronics makers have switched from traditional chemical etching methods to these non-contact fiber lasers instead. Makes sense really, since nobody wants messy chemicals floating around in their production lines anymore.

Case Study: Semiconductor Wafer Marking in Cleanrooms

A 2023 production analysis revealed a leading chipmaker achieved 99.9% mark legibility on 300mm silicon wafers using fiber lasers. The non-contact process eliminated $2.4M/year in contamination-related rejects and maintained <0.1µm surface roughness—essential for 3nm chip fabrication.

Growing Demand for Non-Contact Laser Fiber Marking Solutions

Medical device (23% CAGR) and renewable energy (31% CAGR) sectors account for 54% of new fiber laser purchases in 2024, according to market data. This shift reflects stricter FDA and EU regulations requiring permanent, non-invasive identifiers on implants and solar components.

FAQ

What are fiber laser marking machines?

Fiber laser marking machines are advanced devices used to engrave or mark surfaces with high precision by using a focused laser beam.

How do fiber lasers achieve micron-level precision?

Fiber lasers achieve micron-level precision through focused beam diameters, high-frequency pulsed lasers, and closed-loop galvo scanners that maintain exact positional accuracy.

What materials can fiber lasers mark?

Fiber lasers can mark a variety of materials, including metals, ceramics, polymers, and more, making them versatile for different industries.

Are fiber lasers energy efficient?

Yes, fiber lasers are highly energy-efficient, converting a significant portion of input energy into usable laser light, which reduces energy consumption and costs.