No. 6, Xiaoli Road, Decheng District, Dezhou City, Shandong Province, Chengtou Entrepreneurship Industrial Park +86-15266906570 [email protected]

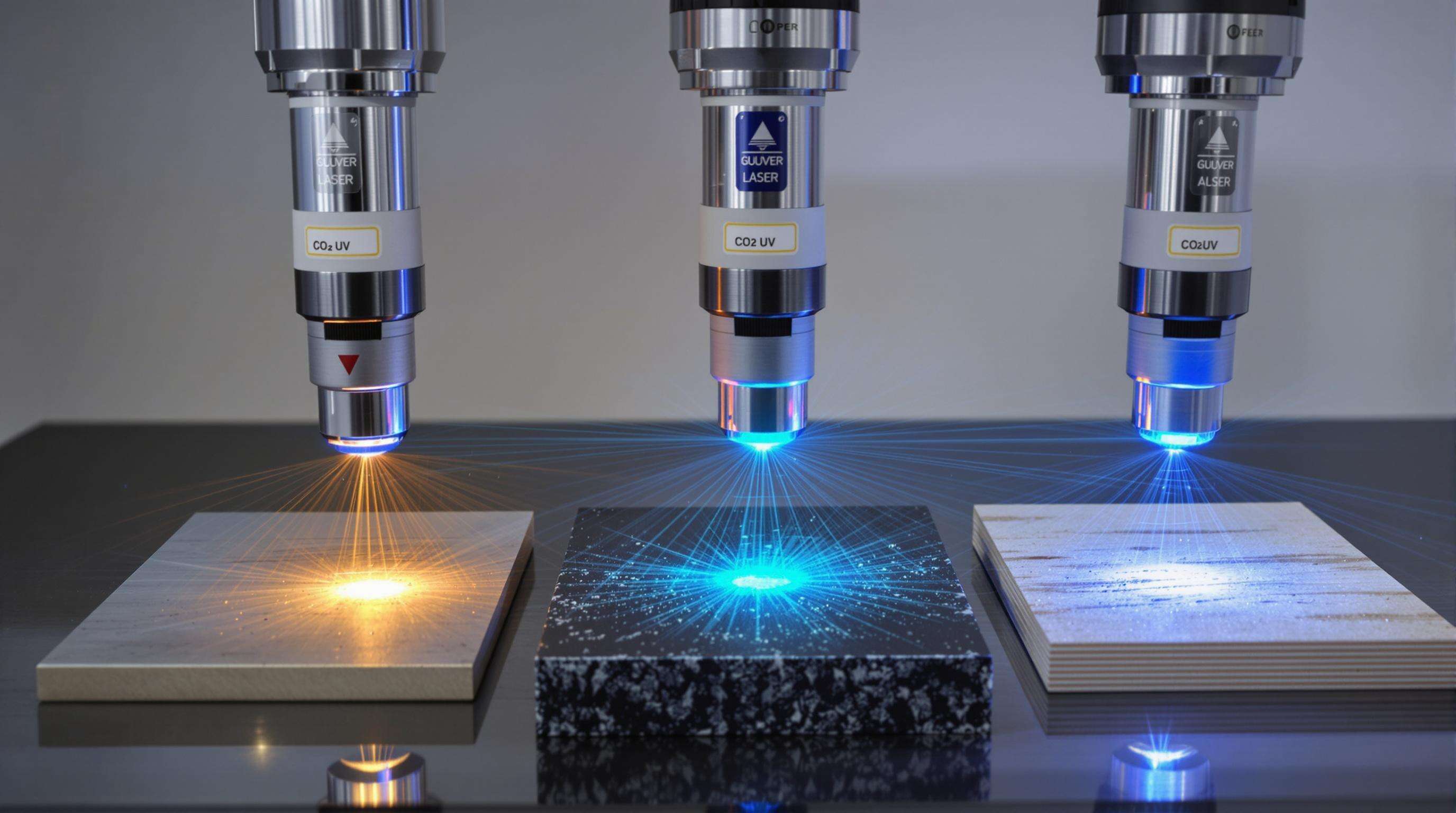

Uv laser marking performance depends on the relationship between wavelength and material absorption properties. Fiber lasers (800-2200 nm wavelengths) excel at marking metals like steel, aluminum, and titanium alloys, while CO₂ lasers (10.6 μm wavelength) target organic materials such as wood, acrylic, and textiles through vibrational energy transfer.

Key differences in material responses:

Three governing principles:

Modern systems now feature wavelength-adjustable modules for marking both metals (1064 nm) and plastics (355 nm), though specialized lasers still outperform in power density (220 kW·cm−² for dedicated fiber lasers).

Ideal for stainless steel, titanium, and anodized aluminum, fiber lasers (1064 nm) achieve ±0.05 mm precision while maintaining structural integrity in nylon, ABS, and polycarbonate.

Dominating wood, paper, and leather processing, CO₂ lasers mark PET packaging films at 1200 characters/second–critical for pharmaceutical coding. Recent improvements enable 300 dpi glass bottle etching.

UV lasers (355 nm) produce 90% contrast marks on medical silicone and 50 μm features on flexible PCBs, reducing heat-affected zones by 80% compared to infrared alternatives (MedTech Innovations 2022).

UV lasers reduce heat-affected zones by 92% on medical polymers through photon energy ablation, as demonstrated in a controlled study.

Fiber lasers have higher upfront costs (35-50% more than CO₂) but save $22,000-$28,000 annually in energy costs during 12-hour daily operation.

Fiber lasers break even in 12-18 months via productivity gains, with $520,000+ five-year savings over CO₂ systems due to faster speeds and reduced waste.

Used in 78% of applications (Ponemon 2023) for VIN etching and FAA-compliant part numbering on durable metals.

92% market penetration for pharmaceutical batch coding and food-safe container marking with <25 µm precision.

Essential for 5 µm semiconductor wafer marking and FDA-compliant UDI codes on medical devices without thermal damage.

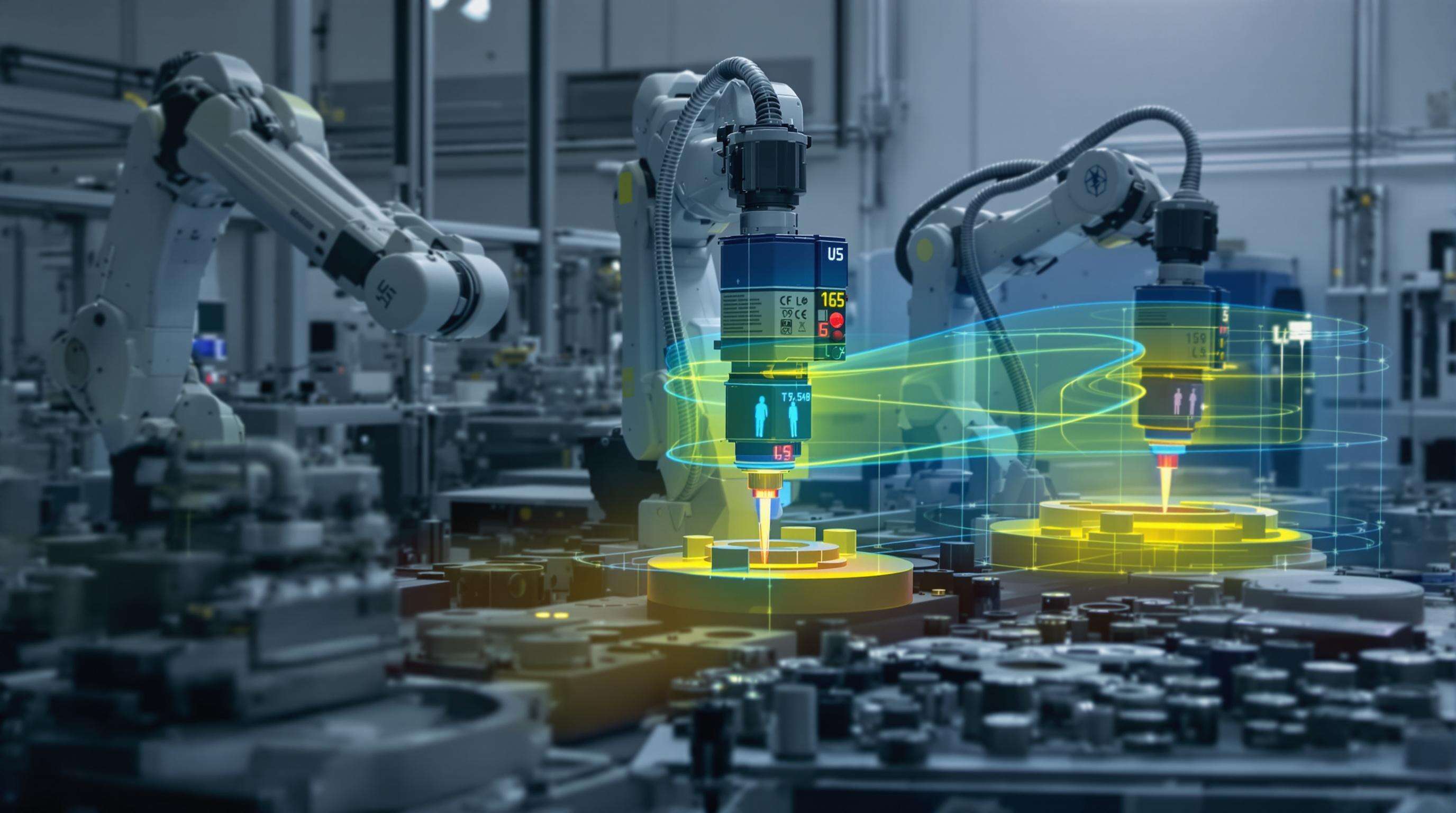

68% of manufacturers now prioritize modular, software-upgradable systems, reducing retooling costs by $740k annually.

Fiber-CO₂ hybrids enable single-pass marking of multi-material assemblies, cutting secondary processing by 37% in aerospace. Cloud-based AI platforms achieve 99.2% first-pass accuracy, shortening validation cycles by 8 weeks for new materials.

For deeper insights into industrial adoption trends, see the 2024 Industrial Marking Report.

The wavelength of a laser determines its suitability for marking different materials. For instance, fiber lasers with wavelengths of 800-2200 nm are ideal for metals, while CO₂ lasers with a 10.6 μm wavelength are better for organic materials.

Modern systems feature wavelength-adjustable modules, allowing them to mark both metals and plastics. However, specialized lasers tend to outperform these in power density and precision.

Fiber lasers, although costlier upfront, save on energy costs in the long term. They also have a longer lifespan and require less maintenance compared to CO₂ and UV lasers.

Copyright © 2025 Dezhou Qijun Automation Equipment Co., Ltd. — Privacy Policy