Integrating Laser Cutting Machines into the Prototype-to-Production Workflow

From design to functional prototype using laser cutting machines

Modern laser cutting machines transform digital designs into functional prototypes within hours. Designers export CAD files directly to laser systems, enabling precise translation of complex geometries into sheet metal components. This direct file transfer eliminates manual interpretation errors and supports rapid design iterations—essential when testing multiple prototype versions.

Bridging rapid prototyping and full-scale production with laser technology

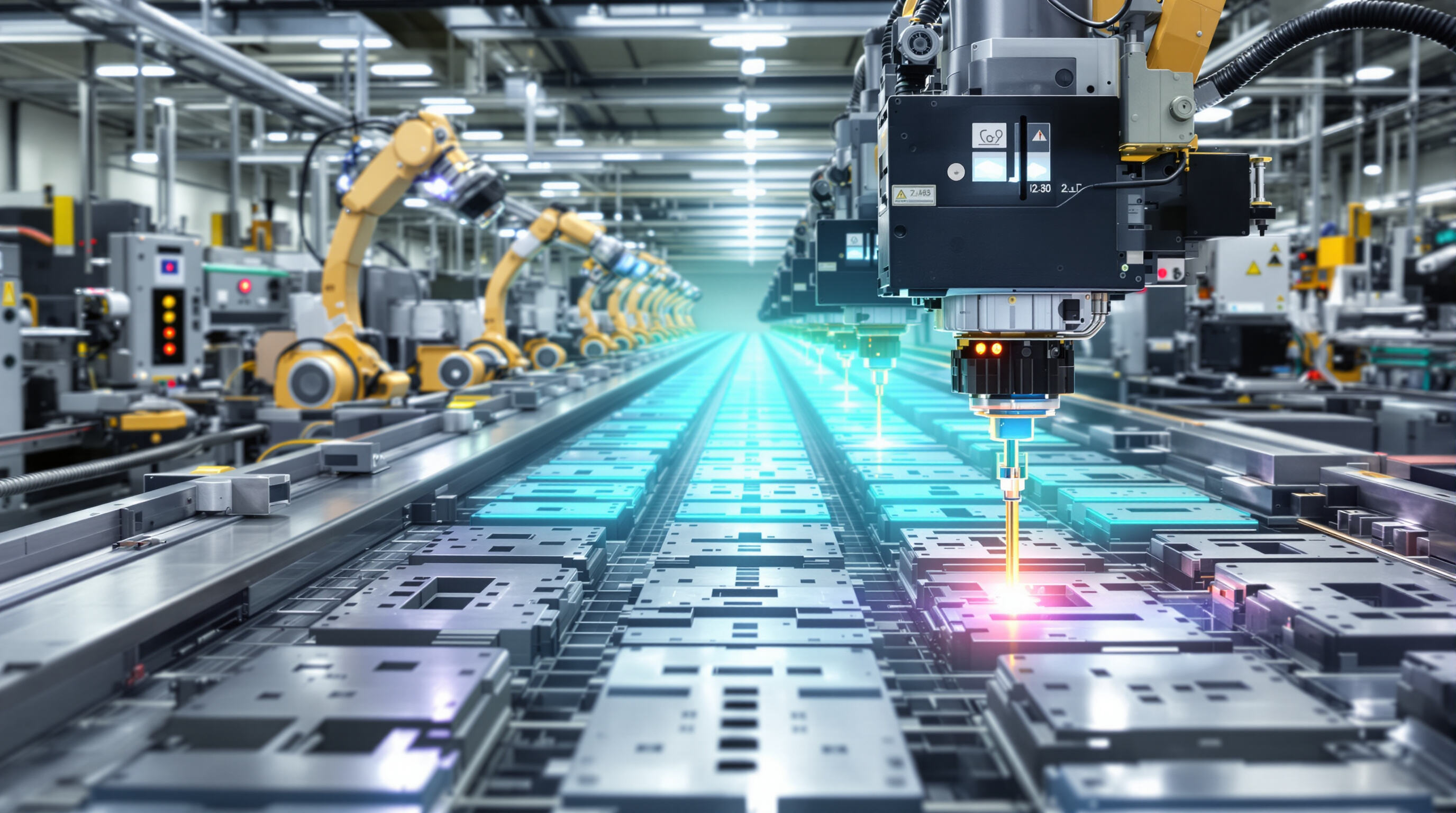

The same laser cutting platform that produces single-unit prototypes can seamlessly scale to high-volume manufacturing. Advanced nesting algorithms automatically optimize material usage patterns for production runs, maintaining prototype-grade precision across thousands of units. This continuity removes traditional bottlenecks caused by transitioning between different prototyping and production tools.

Time savings through CAD/CAM integration in laser cutting workflows

Integrated CAD/CAM systems reduce programming time by 65% compared to manual workflows, according to a 2024 Manufacturing Technology Report. Design modifications propagate automatically through cutting instructions, ensuring all production files stay synchronized. Real-time simulation tools preview cut paths and collision risks before any material is processed.

Scalability: Using the same laser platform from prototype to mass production

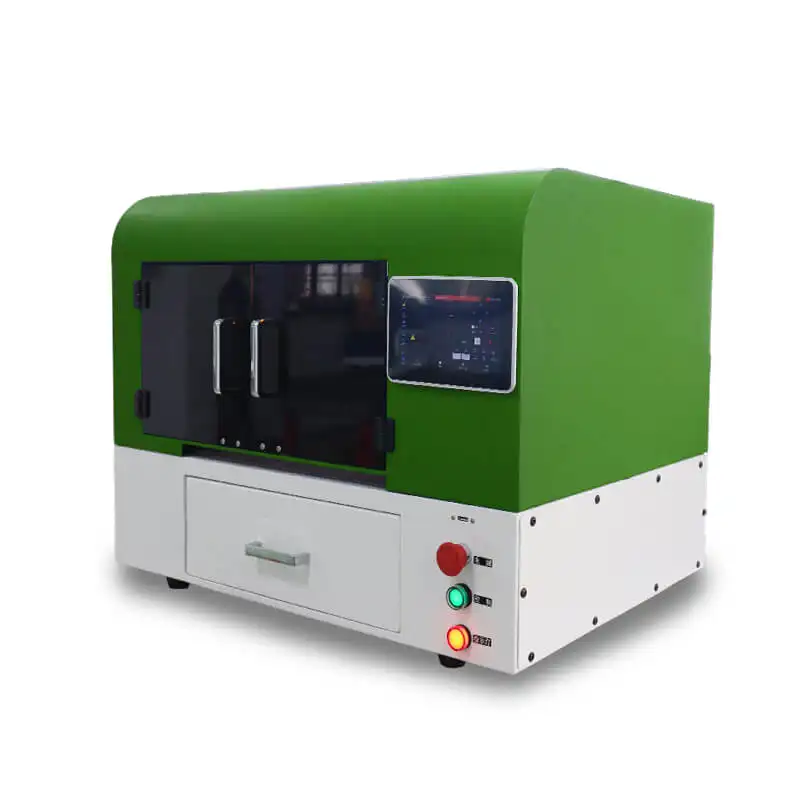

Parametric laser cutting workflows allow engineers to adjust dimensions, material thickness, and tolerance requirements via centralized control panels. A 20kW fiber laser capable of cutting 1mm prototype samples can process 12mm production-grade steel plates simply by adjusting power settings—no hardware changes required.

Case study: Scaling a metal enclosure project from prototype to 5,000 units

A telecommunications manufacturer reduced time-to-market by 40% using laser cutting for both prototyping and production. Initial 5-unit prototypes validated heat dissipation patterns, while automated batch processing delivered 5,000 enclosures with ±0.15mm dimensional consistency. The unified workflow eliminated tooling changeovers typically costing 12–18 production hours per design revision.

Achieving Precision in Metal Fabrication with Laser Cutting Machines

Maintaining tight tolerances in sheet metal fabrication

Laser cutting machines today can achieve around 0.1mm accuracy when working with stainless steel and aluminum, which is good enough for those tough aerospace and medical device requirements. The reason for such precision? These machines cut without physical contact, so there's no tool wear to worry about. Plus they have this smart focus control system that keeps the cut width consistent even through materials as thick as 25mm. Some recent research from 2023 showed something interesting too. When making complicated shapes, parts cut with lasers needed almost half (about 42%) less finishing work compared to ones made with plasma cutting. That kind of difference adds up over time for manufacturers dealing with intricate designs.

Cutting complex and intricate designs with high repeatability

Fiber lasers hit around 99.8% accuracy when replicating shapes throughout production batches because they use closed loop motion controls plus thermal compensation tech. Even really detailed parts such as those tiny 0.5 mm air vents or complex interlocking pieces can now be made in bulk without needing constant adjustments to tools. According to what manufacturers are finding these days, switching from traditional stamping methods to laser cutting cuts down on design limitations by roughly 60% during early prototype development stages. This means designers have much more freedom to experiment with complicated geometries that would otherwise be impossible with conventional manufacturing approaches.

Consistent accuracy: ±0.1mm across stainless steel and aluminum

Advanced cutting heads automatically adjust assist gas pressure and nozzle height when switching between reflective aluminum (5052 alloy) and high-carbon steels (304 stainless). Pulse-shaping technology prevents edge warping in thin-gauge materials while maintaining cut speed—critical for electronics enclosures requiring burr-free 1.6mm aluminum panels.

Balancing high precision with production speed in industrial applications

Today's 6kW fiber lasers cut 3mm mild steel at 35m/minute while holding ±0.15mm positional accuracy, allowing automotive suppliers to produce 1,200 door components per hour with full dimensional compliance. Real-time beam monitoring systems automatically compensate for focal lens contamination, ensuring consistent performance over extended 24/7 operations without manual recalibration.

Key Advantages of Laser Cutting for Sheet Metal Prototyping

Accelerating development cycles with rapid laser prototyping

Laser cutting compresses prototyping timelines by converting CAD files directly into finished parts within hours, bypassing traditional tooling. A 2023 manufacturing survey revealed 63% of engineering teams reduced prototype development time by 40–60% after adopting laser systems. This rapid turnaround enables 5–7 design iterations weekly, significantly outpacing the 1–2 cycles typical with mechanical methods.

Reducing material waste and lowering costs in short-run production

Non contact processes can get material usage rates between 92% and 97%, thanks to those smart nesting algorithms. This really makes a difference for companies working with costly materials such as titanium or special alloy blends during their prototype phase. The kerf width is super narrow too, around just 0.15mm, which means parts fit together much tighter on each sheet than what we see with plasma cutting or water jets according to recent fabrication reports. When looking at smaller production runs below 50 pieces, all these improvements translate into real money saved on raw materials somewhere between $240 to $380 for every batch produced.

Adapting quickly to design changes during iterative prototyping phases

Fiber laser systems these days will adjust cutting settings on their own whenever someone changes CAD designs, so there's no waiting around for manual recalibration anymore. According to a study done last year, manufacturing teams working with laser prototypes managed to fix about 86 out of every 100 design problems before making physical tools, whereas old fashioned mockups only caught around half those issues. The speed of response really works hand in glove with modern agile methods, which is why certain car part makers have been hitting their design completion targets roughly 30 percent quicker than they used to. Some shops even report being able to iterate through multiple design versions in a single day thanks to this kind of real time feedback loop.

Material Compatibility and Performance Across Metals

Comparing Laser Cutting Performance on Stainless Steel, Aluminum, and Carbon Steel

The way laser cutting works varies quite a bit depending on what kind of metal we're dealing with because each has different characteristics. Take stainless steel for instance, which typically ranges from 0.5 to 12 mm thick. Industrial shops can get pretty accurate cuts here, around ±0.1 mm precision, since stainless doesn't conduct heat as readily as other metals do. Compare that to aluminum's thermal conductivity of 205 W/mK versus just 16 W/mK for stainless steel. Aluminum presents another challenge altogether. The reflective surface means manufacturers need more powerful lasers, but once that hurdle is cleared, it opens up possibilities for creating intricate designs quickly sometimes reaching cutting speeds of about 40 meters per minute. Carbon steel remains popular for structural components mainly because it costs less, but there's a catch. Without proper gas assistance during cutting, oxidation becomes a real problem. Most shops solve this by using fiber lasers combined with nitrogen purging techniques. Recent research published in the Journal of Materials Processing back in 2023 supports these findings and confirms how effective these methods have become across various manufacturing settings.

Thermal Effects and Edge Quality in Different Conductive Metals

The way materials handle heat has a real effect on how clean those cuts end up being. Take stainless steel for instance it doesn't transfer heat as fast which actually helps focus the energy better resulting in smoother edges around 1.6 microns roughness average. Aluminum tells a different story though because it conducts heat so well we need to adjust our laser pulses carefully otherwise we get all that pesky dross buildup. Copper alloys throw another wrench into things altogether. Some shops have found they need to slow down their cutting speed by about 15 to 20 percent just to keep control over how the heat spreads out (Thermal Analysis Society looked at this back in 2022). Getting those machine parameters right makes a big difference too. Shops report shrinking those heat affected areas anywhere from 30 to 50 percent when working with metals that conduct electricity well.

Fiber vs. CO2 Lasers: Evaluating Efficiency for Thin Aluminum Prototypes

When working with thin aluminum parts under 3mm thick, fiber lasers are the go to choice because of their 1070 nm wavelength. This wavelength gets absorbed about three times better in aluminum compared to traditional CO2 laser systems. According to recent research from 2024, these fiber lasers cut down on electricity bills by around 40 percent and maintain almost perfect consistency at 99.8% repeatability when cutting 0.8mm aluminum enclosures. That said, CO2 lasers still have their place in production lines that handle multiple materials together. But manufacturers should be aware that running CO2 systems tends to cost about 25% more in maintenance expenses over time since the mirrors inside degrade faster when used extensively in busy manufacturing settings.

Automation and Quality Control in Laser-Based Manufacturing

Reducing Human Error Through Automated Laser Cutting Systems

Laser cutting machines today rely heavily on robotics to handle materials and smart software that sets parameters automatically. The automation really cuts down on mistakes during setup time. According to some industry reports from LinkedIn in 2025, these systems slash error rates by about two thirds compared to what happens when people do it manually. When dealing with tricky materials such as titanium, even tiny differences matter a lot. We're talking about measurements down to 0.05 millimeters making all the difference between something working properly or failing completely.

Ensuring Consistency With Real-Time Monitoring and Feedback Loops

Modern manufacturing setups now incorporate multispectral sensors alongside high speed cameras that can run upwards of 200 quality inspections every single minute throughout the production process. According to research published last year in Today's Medical Developments, when applying real time thermal monitoring techniques to stainless steel fabrication work, manufacturers saw a significant drop in material warping issues by around 41 percent. The same study noted they maintained impressive precision levels with only +/- 0.08 mm deviation across entire 18 hour shifts. These smart systems feature feedback mechanisms that constantly tweak things like gas pressure settings and laser focus points as materials come through the line, helping compensate for those inevitable variations we all know happen in actual production environments.

Emerging Trend: AI-Driven Calibration in Modern Laser Cutting Machines

Leading manufacturers now employ machine learning models that predict optic degradation and nozzle wear. Unlike fixed maintenance schedules, these systems perform self-calibration during tool changes, improving beam quality consistency by 29% in high-volume aluminum applications. Early adopters report 97% first-pass yield rates when combining AI calibration with automated inspection protocols.

FAQs

What are the key benefits of using laser cutting machines for prototyping?

Laser cutting machines offer high precision, rapid prototyping, and can directly transform CAD files into finished parts. They support complex geometries and fast design iterations.

How do laser cutting machines improve production scalability?

Laser cutting machines can seamlessly transition from creating single-unit prototypes to high-volume production without requiring different tools, thanks to advanced nesting algorithms and scalable laser power settings.

Can laser cutting machines handle different metals effectively?

Yes, laser cutting machines are equipped to handle various metals such as stainless steel, aluminum, and carbon steel by adjusting laser power, pulse shaping, and assist gas settings for optimal performance.

What role does automation play in laser-based manufacturing?

Automation in laser-based manufacturing reduces human error, enhances precision with real-time monitoring, and supports fast adjustments to production parameters, ensuring high yield and consistency.

Why choose fiber lasers over CO2 lasers for thin aluminum cutting?

Fiber lasers are more efficient for thin aluminum due to better energy absorption and lower operational costs compared to CO2 lasers, which are more suitable for multi-material production lines but with higher maintenance expenses.

Table of Contents

-

Integrating Laser Cutting Machines into the Prototype-to-Production Workflow

- From design to functional prototype using laser cutting machines

- Bridging rapid prototyping and full-scale production with laser technology

- Time savings through CAD/CAM integration in laser cutting workflows

- Scalability: Using the same laser platform from prototype to mass production

- Case study: Scaling a metal enclosure project from prototype to 5,000 units

- Achieving Precision in Metal Fabrication with Laser Cutting Machines

- Key Advantages of Laser Cutting for Sheet Metal Prototyping

- Material Compatibility and Performance Across Metals

- Automation and Quality Control in Laser-Based Manufacturing

-

FAQs

- What are the key benefits of using laser cutting machines for prototyping?

- How do laser cutting machines improve production scalability?

- Can laser cutting machines handle different metals effectively?

- What role does automation play in laser-based manufacturing?

- Why choose fiber lasers over CO2 lasers for thin aluminum cutting?