ผลงานทางความร้อน: ประสิทธิภาพในการเย็นและความมั่นคงภายใต้ภาระสําหรับเครื่องปั่นเลเซอร์ที่เย็นด้วยอากาศและเลเซอร์ที่เย็นด้วยน้ํา วิธีการปรับความเย็นด้วยน้ําทําให้การผลิตพลังงานสูงที่ยั่งยืน เครื่องปั่นเลเซอร์ที่เย็นด้วยน้ําใช้ประโยชน์จากวิธีการของเหล

ดูเพิ่มเติม

เหตุใดเลเซอร์ระบายความร้อนด้วยน้ำจึงจำเป็นต่อการจัดการความร้อนอย่างเชื่อถือได้ในการเชื่อมแผ่นหนา ขีดจำกัดด้านความร้อน: เหตุใดเลเซอร์ระบายความร้อนด้วยอากาศจึงล้มเหลวเมื่อความหนาของแผ่นเกิน 20 มม. เมื่อทำงานกับแผ่นที่หนากว่าประมาณ 20 มม. ระบบเลเซอร์ระบายความร้อนด้วยอากาศจะถึงขีดจำกัดด้านความร้อน...

ดูเพิ่มเติม

เหตุใดอลูมิเนียมและทองแดงจึงท้าทายการตั้งค่าเครื่องทำเครื่องหมายด้วยไฟเบอร์เลเซอร์มาตรฐาน การสะท้อนแสงสูงและความนำความร้อนสูง: อุปสรรคจากหลักฟิสิกส์ที่ทำให้ไม่สามารถทำเครื่องหมายได้อย่างสม่ำเสมอ การทำงานกับอลูมิเนียมและทองแดงมีความท้าทายจริง ๆ สำหรับเครื่องทำเครื่องหมายด้วยไฟเบอร์เลเซอร์มาตรฐาน...

ดูเพิ่มเติม

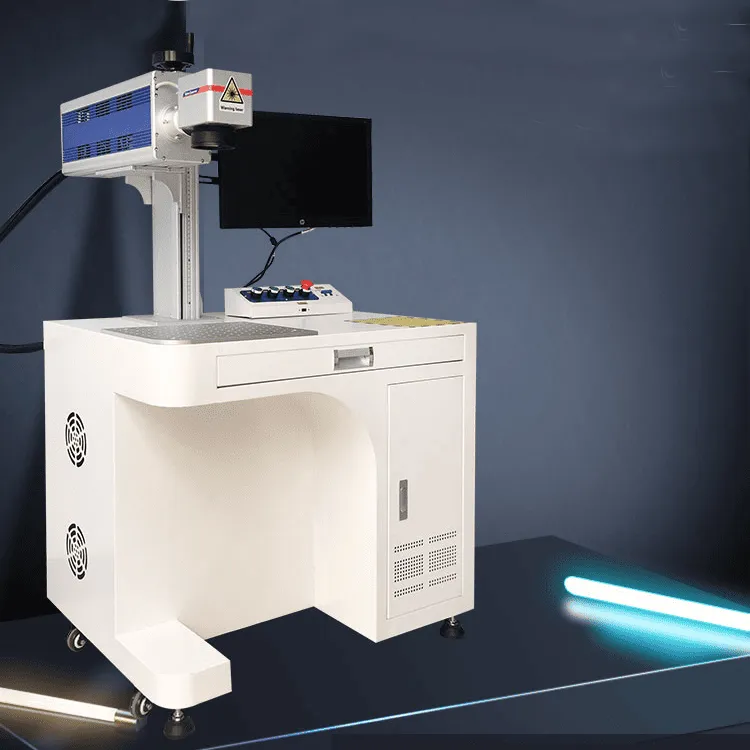

การทำเครื่องหมายถาวรบนโลหะด้วยเครื่องทำเครื่องหมายด้วยไฟเบอร์เลเซอร์ เครื่องทำเครื่องหมายด้วยไฟเบอร์เลเซอร์สร้างการระบุตัวตนที่ลบไม่ออกบนชิ้นส่วนโลหะโดยอาศัยปฏิกิริยาโฟโตเทอร์มอลขั้นสูง—เพื่อให้มั่นใจว่าข้อมูลการติดตามที่สำคัญจะคงอยู่ตลอดอายุการใช้งานของชิ้นส่วน

ดูเพิ่มเติม

เครื่องเลเซอร์แกะสลัก CO₂: ไม่มีลำแสงออกหรือเผาไหม้เป็นช่วง ๆ – วิธีแก้ปัญหาการล้มเหลวของลำแสงเลเซอร์ หลอดเลเซอร์ไม่ติด: การตรวจสอบแหล่งจ่ายไฟ, ฟิวส์ และความสมบูรณ์ของวงจรแรงดันสูง หากเครื่องแกะสลักเลเซอร์ CO2 เริ่มต้นไม่ได้อย่างเหมาะสม เครื่อง...

ดูเพิ่มเติม

ผลกระทบของกลไกการระบายความร้อนต่อประสิทธิภาพเครื่องเชื่อมเลเซอร์ระบายความร้อนด้วยน้ำ การทำงานหลักของเครื่องเชื่อมไฟเบอร์เลเซอร์ที่ระบายความร้อนด้วยอากาศ เครื่องเชื่อมไฟเบอร์เลเซอร์ที่ระบายความร้อนด้วยอากาศทำงานโดยใช้การเคลื่อนไหวของอากาศตามธรรมชาติร่วมกับพัดลมที่เป่าลมผ่านชิ้นส่วนที่ร้อน เช่น อุปกรณ์ขับเคลื่อน...

ดูเพิ่มเติม

เครื่องแกะสลักด้วยเลเซอร์เปลี่ยนโฉมอุตสาหกรรมการผลิตเครื่องประดับอย่างไร เปลี่ยนวิธีการแบบดั้งเดิมด้วยความแม่นยำและประสิทธิภาพ อุตสาหกรรมเครื่องประดับกำลังประสบกับการเปลี่ยนแปลงครั้งใหญ่ด้วยเครื่องแกะสลักด้วยเลเซอร์ ซึ่งเข้ามาแทนที่วิธีการทำด้วยมือแบบเก่า...

ดูเพิ่มเติม

ทำความเข้าใจเกี่ยวกับความเข้ากันได้ของวัสดุกับเครื่องทำเครื่องหมายด้วยไฟเบอร์เลเซอร์ วัสดุใดให้ผลลัพธ์ดีที่สุด: โลหะ พลาสติก และเซรามิก การทำเครื่องหมายด้วยไฟเบอร์เลเซอร์ทำงานได้ดีมากกับโลหะหลายชนิด รวมถึงเหล็กกล้าไร้สนิม อลูมิเนียม ทองเหลือง และวัสดุที่ทนทานอื่นๆ...

ดูเพิ่มเติม

ทำความเข้าใจเกี่ยวกับเครื่องเชื่อมเลเซอร์ระบายความร้อนด้วยน้ำและบทบาทของมันในการผลิตโลหะ ส่วนประกอบหลักและการทำงานของเครื่องเชื่อมเลเซอร์ระบายความร้อนด้วยน้ำ เครื่องเชื่อมเลเซอร์ระบายความร้อนด้วยน้ำรวมเอาส่วนสำคัญหลายประการเข้าไว้ด้วยกัน เช่น เลเซอร์จริง...

ดูเพิ่มเติม

ระบบระบายความร้อนด้วยน้ำช่วยเพิ่มสมรรถนะและความเสถียรในเครื่องเชื่อมเลเซอร์ระบายความร้อนด้วยน้ำได้อย่างไร ทำไมเลเซอร์จึงต้องมีการระบายความร้อนเพื่อรักษาระบบการทำงานให้มีเสถียรภาพ เครื่องเชื่อมเลเซอร์สร้างความร้อนจำนวนมากขณะทำงาน ดังนั้นการระบายความร้อนจึงมีความสำคัญอย่างยิ่ง...

ดูเพิ่มเติม

การแก้ปัญหาการไหลของโลหะเชื่อมและการรักษาความแข็งแรงของข้อต่อโดยใช้เครื่องเชื่อมเลเซอร์สำหรับเครื่องประดับ การสำรวจเทคนิคช่างทองคำในปี 2023 พบว่าประมาณหนึ่งในสามของเครื่องประดับที่ทำด้วยมือมีปัญหา เช่น การไหลของโลหะเชื่อมที่ไม่สม่ำเสมอ หรือข้อต่อที่อ่อนแอ เครื่องเชื่อมด้วยเลเซอร์...

ดูเพิ่มเติม

วิวัฒนาการของการผลิตเครื่องประดับ: เครื่องเชื่อมเลเซอร์แบบพกพาเปลี่ยนเกมอย่างไร จากการบัดกรีแบบดั้งเดิมสู่เทคโนโลยีเลเซอร์ที่แม่นยำ ในอดีต ช่างทำเครื่องประดับใช้ไฟแช็กและลวดเชื่อมทั่วไป ซึ่งมักทำให้โลหะบางชนิดเสียรูปหรือ...

ดูเพิ่มเติมลิขสิทธิ์ © 2025 เดซั่ว ฉีจวิน ออโตเมชั่น อีควิปเมนท์ คอ., ลิมิเต็ด — นโยบายความเป็นส่วนตัว