Top Application Areas of Metal Laser Cutting Machines

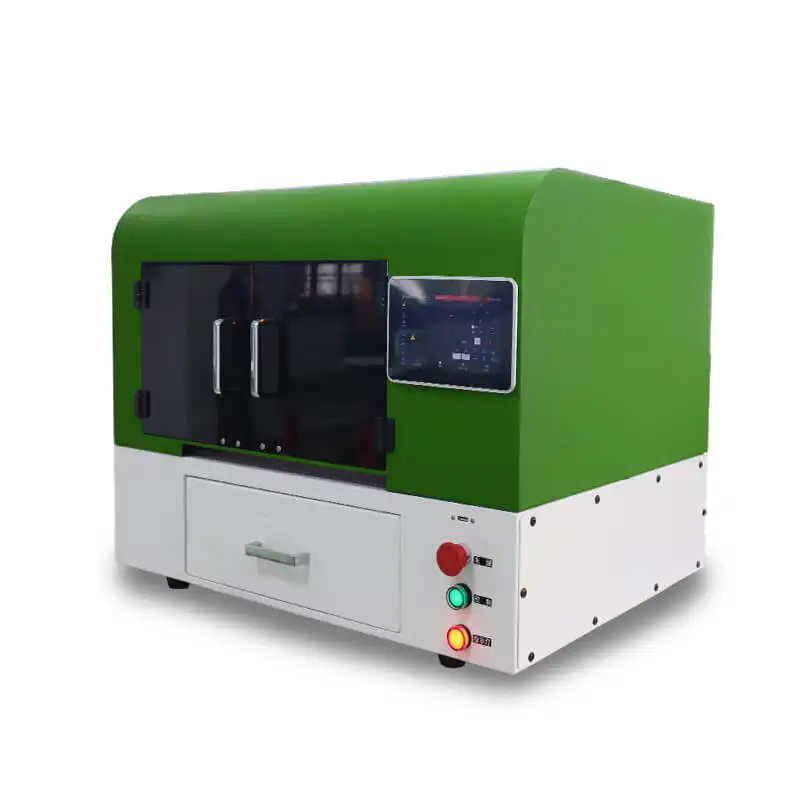

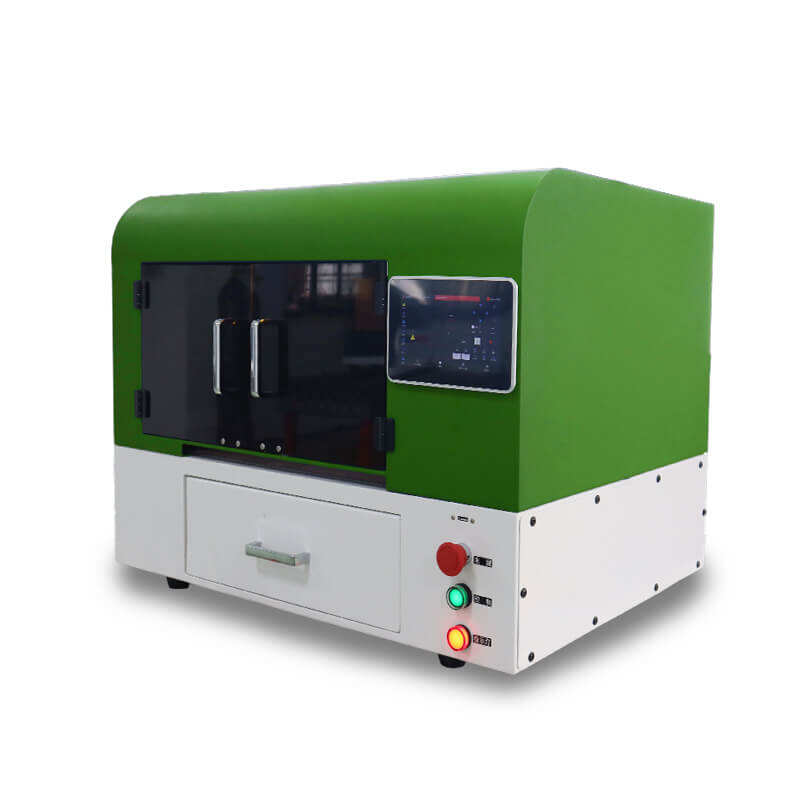

1. Metal Fabrication & Industrial Manufacturing

Metal laser cutting machines are widely used in metal fabrication shops, industrial manufacturing, and heavy machinery production for cutting carbon steel, stainless steel, aluminum, and alloy metals with high precision. These machines excel in producing structural components, brackets, enclosures, and machine parts with tight tolerances (±0.1mm), ensuring fast turnaround and consistent quality. Industries such as construction, heavy equipment, and plant machinery rely on fiber laser cutters to optimize material usage, reduce waste, and accelerate production timelines. Whether it's thick steel plates (up to 30mm) or thin sheets (0.5-5mm), metal laser cutters deliver clean, burr-free edges without the need for secondary processing.

2. Automotive & Aerospace Industry

In the automotive and aerospace sectors, precision and material integrity are critical—making metal laser cutting machines indispensable. These machines are used to cut precision parts such as chassis components, engine mounts, exhaust systems, and body panels from high-strength steels, aluminum alloys, and titanium. The high-speed cutting (up to 100m/min) and micro-precision (±0.05mm) capabilities ensure perfect fitment and structural integrity for safety-critical components. Additionally, aerospace manufacturers leverage fiber laser cutters to process thin-gauge aluminum, Inconel, and Hastelloy alloys for aircraft frames, turbine blades, and hydraulic systems, where minimal heat-affected zones (HAZ) and distortion are essential.

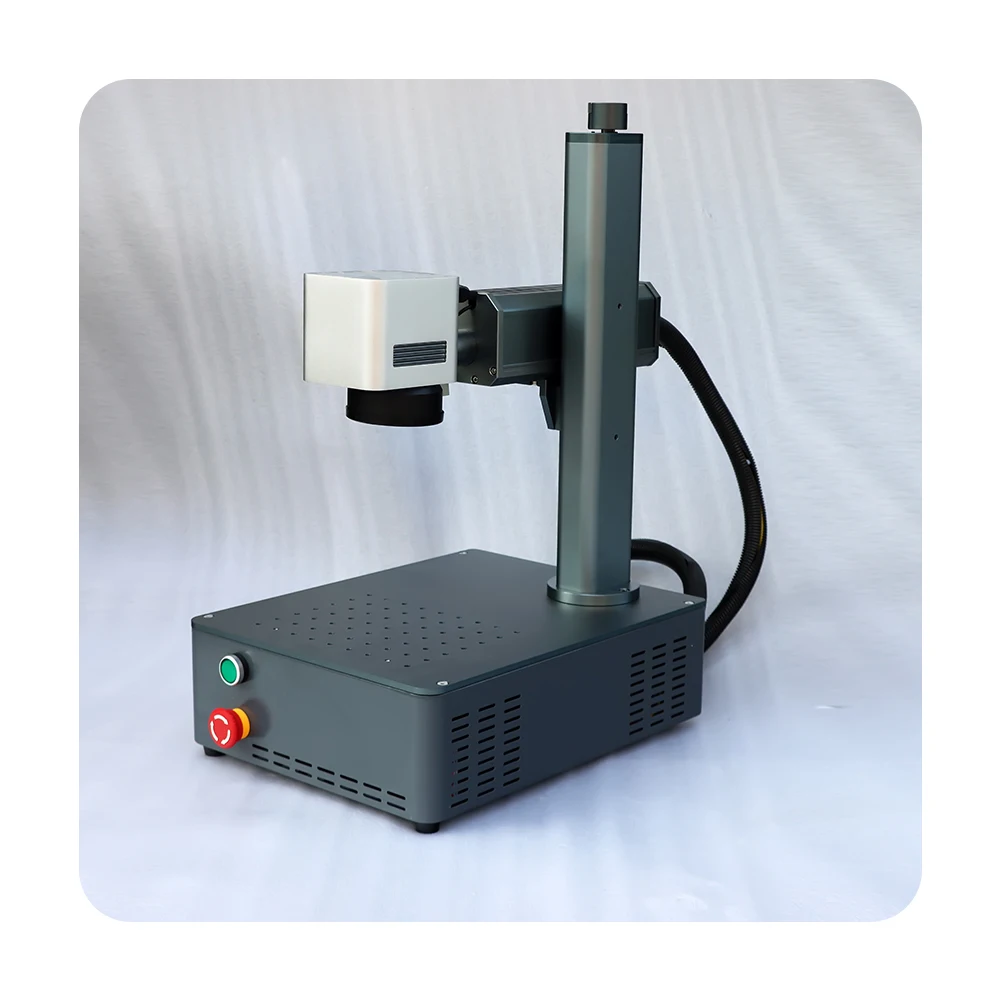

3. Custom Metalworking, Signage & Decorative Applications

Beyond industrial use, metal laser cutting machines are also popular in custom metal fabrication, architectural metalwork, signage, and decorative arts. Artisans and designers use CNC metal laser cutters to create intricate patterns, logos, and 3D metal sculptures from stainless steel, brass, and copper. The non-contact cutting process ensures no mechanical stress, preserving the material’s finish and structural strength. Businesses in the furniture, interior design, and retail industries utilize these machines to produce custom metal shelves, railings, elevator panels, and branded metal signage with high detail and smooth edges. Whether for mass production or one-off bespoke projects, metal laser cutters provide unmatched versatility, speed, and precision across diverse applications.