Why Choose Us

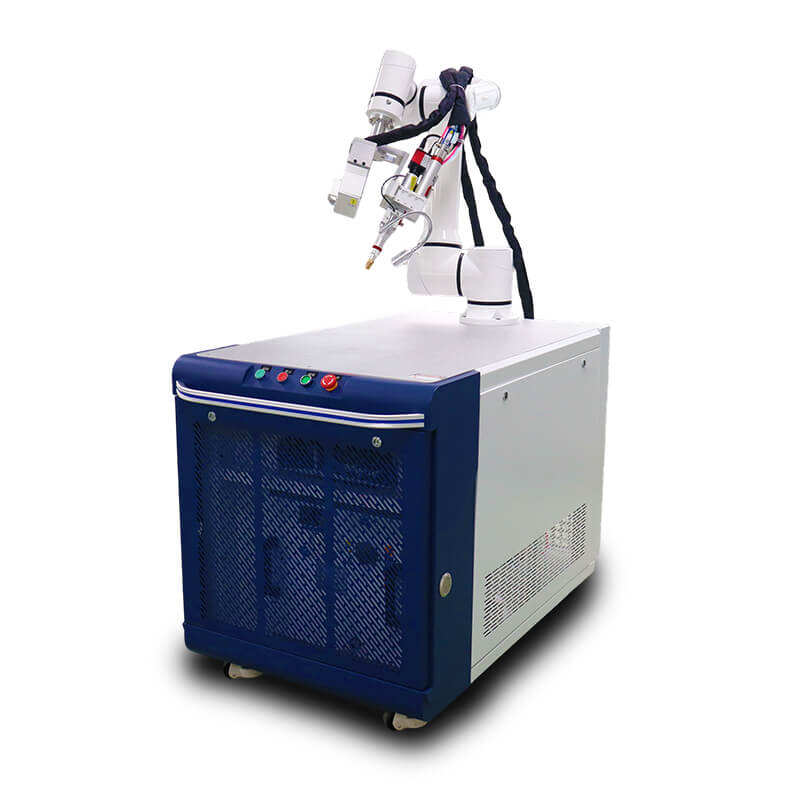

Shandong JuMing Automation Equipment Co.,Ltd’ is an integrated enterprise with production, sales and service. Have provides You with considerate, reliable, and comprehensive active after-sales service laser marking solutions.

Our company is mainly produced all kinds of laser marking machine, fiber laser marking machine, co2 laser marking machine, marking machine, purple lights and many other different kinds of marking machine's design, technology, and advaited level at home and abroad, strong technical force, high-quality skilled workers, superb technology, advanced production equipment to meet the user requirements.