Laser cutting machines serve a variety of industries, for the accurate cutting of materials. Commonly laser cut materials are metals, woods, acrylics, and fabrics. There are 4 major steps to operate a laser cutting machine; preparation, setup, cutting, and post process. Each phase is important for good cutting and good operation;

1. Pre-operation PreparationFor laser cutting machines, pre-operation preparation is an important step. This ensures cutting accuracy and safe operation of the laser cutting machine.

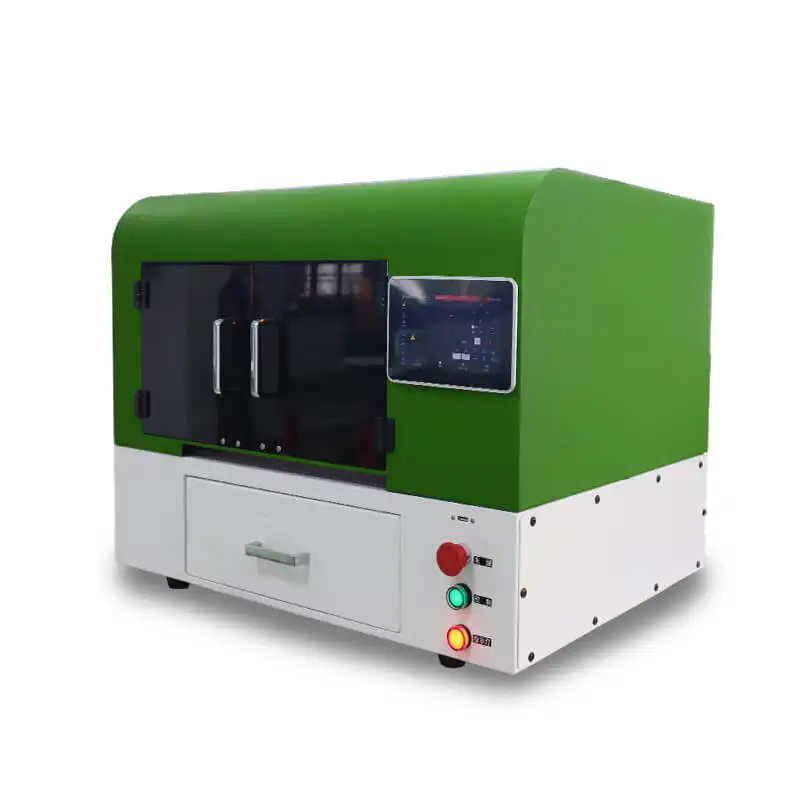

1.1 First we should check the all equipment.Including the stopping buttons, the protect covers and laser safe interlocks. Make sure all of this system function. It is not alone have bad work during our cutting and also we have the system for exhaust gas. Finally wear proper professional equipment, which including laser safe glasses, gloves, and non-flammable clothing.

1.2 Check the materials flatness to be cut. Check the materials cleanliness, and if the material is laser compatible. CO₂ lasers will cut through most non-metal materials while fiber lasers handle most types of metals. Also check that the surface of the material is free from any contaminants. Contaminants, like dust or oils, could affect cutting accuracy or create hazards (fires).

1.3 Machine Power-UpTo power up the machine, turn on the MAIN power switch. Next power the auxiliary systems on; this consists of the laser generator, the cooling system (for fiber lasers), and the exhaust fan. After powering on, wait for the machine to complete its powering on process, and the manufacturer will indicate a warm up time (if required).

2. Workpiece Set-Up

The first consideration is how to accurately set-up the workpiece.

2.1 Workpiece FixingThe workpiece, or the material that you are cutting, needs to be secured appropriately on the machine including the worktable. The material naturally needs to be held in place with either clamps if possible, or we recommend using vacuum chucks or honeycomb panels if the material is thin enough. This will help mitigate movement during the cutting phase. It is also important to make sure that the material is flat, and aligned on the X/Y axes of the machine to help avoid potential cutting failures due to the workpiece being installed incorrectly.

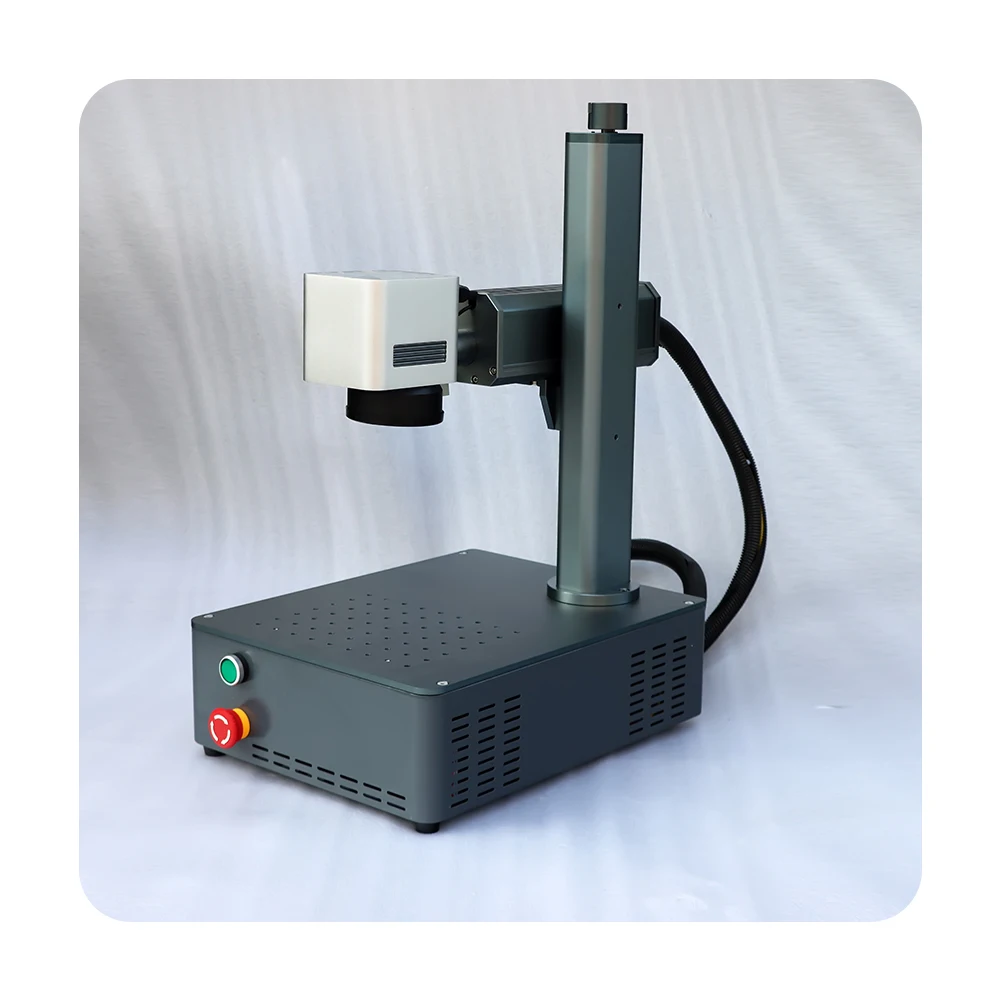

2.2 Laser Focus SettingYou can set the laser head height to create the correct focal length which is the distance from the lens to the surface of the material. The focal length will change depending on the material that you are working with, and will also depend on the model of laser system you are using as well. Use manual focus tool of the machine, or the auto focus function if available for maximum accuracy. Incorrect focal settings can cause cutting flaws, such as a rough edge or not completely cutting through the material, etc.