The Importance of Affordable Laser Welding Machines: A Strategic Tool Driving the Revolution in Small-Scale Manufacturing

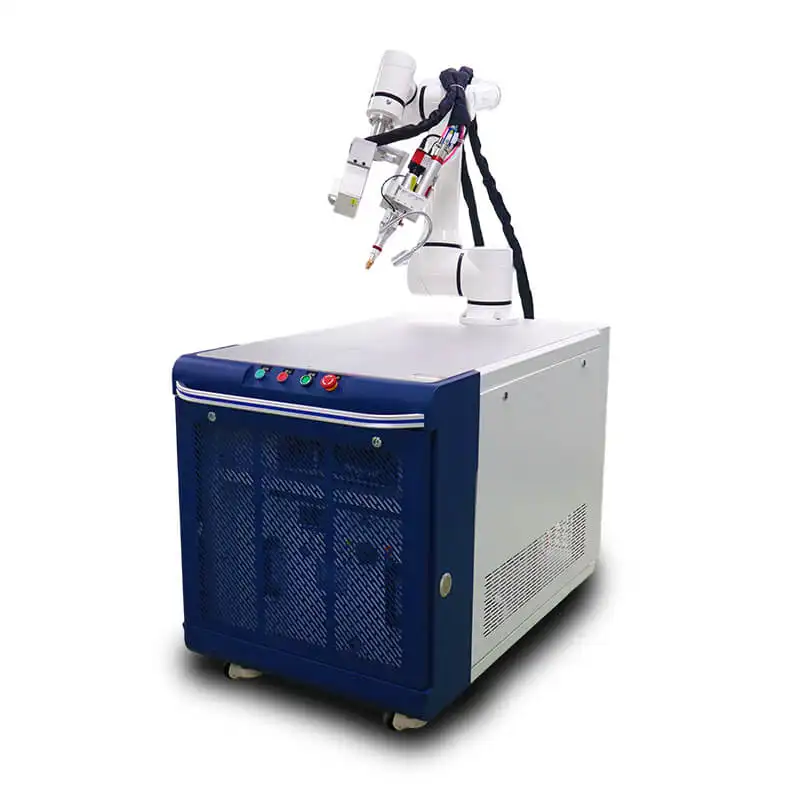

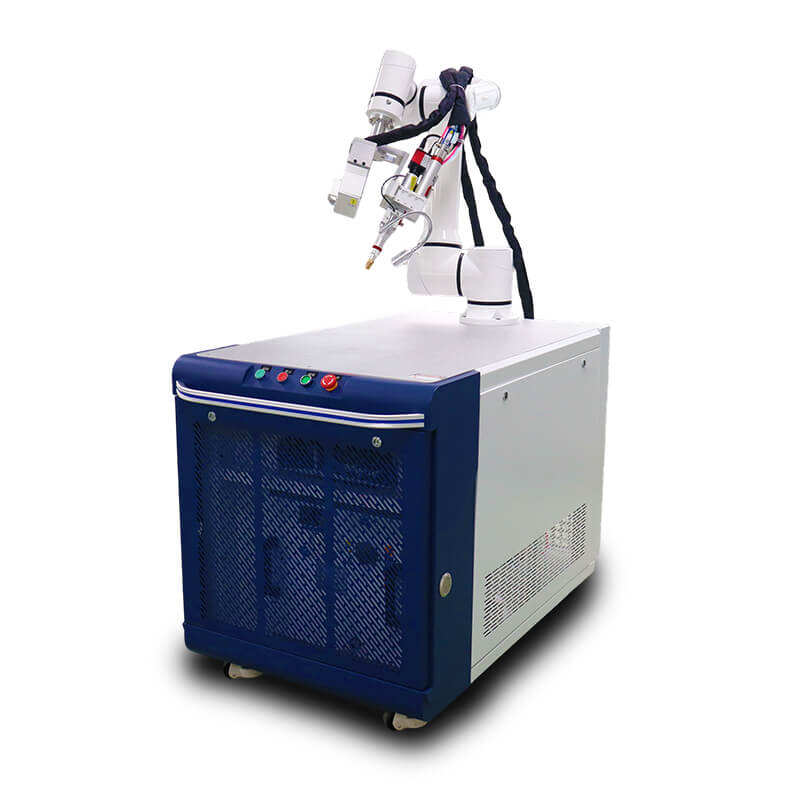

For small and medium-sized manufacturers, independent studios, and entrepreneurs, the high cost of industrial-grade production equipment has long been an insurmountable barrier. The emergence of affordable laser welding machines has completely transformed this landscape, compressing what was once a professional-grade technology costing tens of thousands of dollars into an accessible price range of under $5,000. These devices are far from being synonymous with “cheap and low-quality”—they feature air-cooled fiber technology capable of achieving ultra-fine welding at 0.01-0.2mm, capable of handling jewelry-grade 0.1mm copper foil as well as 4mm stainless steel structural components, enabling micro-workshops to undertake high-value-added orders such as medical devices and new energy batteries.

Compared to traditional arc welding, the 70% reduction in overall costs achieved through laser welding is particularly significant: the absence of protective gas and consumable welding materials reduces the cost per inch of welding to as low as $0.03; the near-zero thermal deformation of cold processing eliminates 80% of post-processing labor hours. South African automotive repair shop Thabo is a prime beneficiary—using a $3,200 device, they successfully repaired high-end alloy wheels, transforming orders previously outsourced to large factories into a profitable growth opportunity, achieving a return on investment within six months.

In the era of agile manufacturing, these desktop-sized devices, occupying less than 0.5 square meters, demonstrate remarkable scalability. Startup teams can first use thousand-dollar-level equipment to take on small-batch custom orders (such as welding titanium alloy eyeglass frames), and as the business expands, they can upgrade laser power or add rotary axes through modular upgrades to gradually build automated production lines. This “gradual investment” model perfectly avoids the cash flow risks associated with heavy asset investments for small businesses while ensuring they always stay half a step ahead of competitors: While traditional welders are still grinding weld seams, laser users have already completed precision medical device sealing welding, securing critical contracts at five times the speed of arc welding.

It is worth noting that while entry-level equipment lags behind industrial-grade systems in peak power (typically ≤1500W) and continuous operating time, modern affordable models already cover 85% of daily production needs. Especially for space-constrained urban maker spaces or educational institutions, their energy consumption of <1.5 kW is comparable to household appliances, yet they can achieve aerospace-level connection processes in a garage environment—this is the true victory of technological democratization: making cutting-edge manufacturing capabilities no longer constrained by capital scale, but instead becoming a productivity lever within reach of every hands-on practitioner.