Why Choose Us

1. Business diversification: The company does not only sell industrial automatic control system devices, packaging specialized equipment, and office equipment consumables; it also involves licensed businesses in projects such as health food sales and export and import of products.

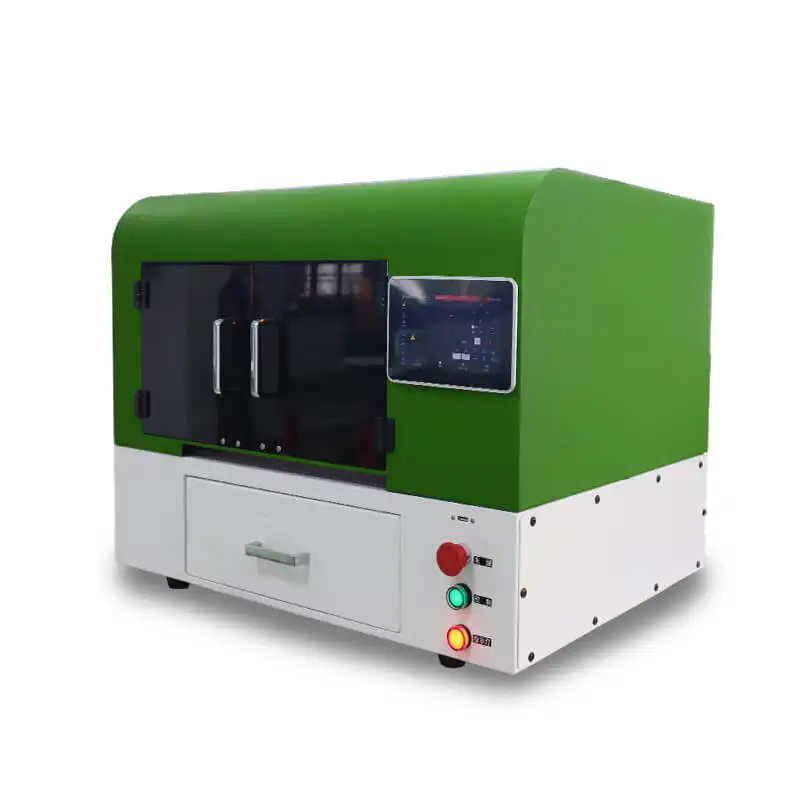

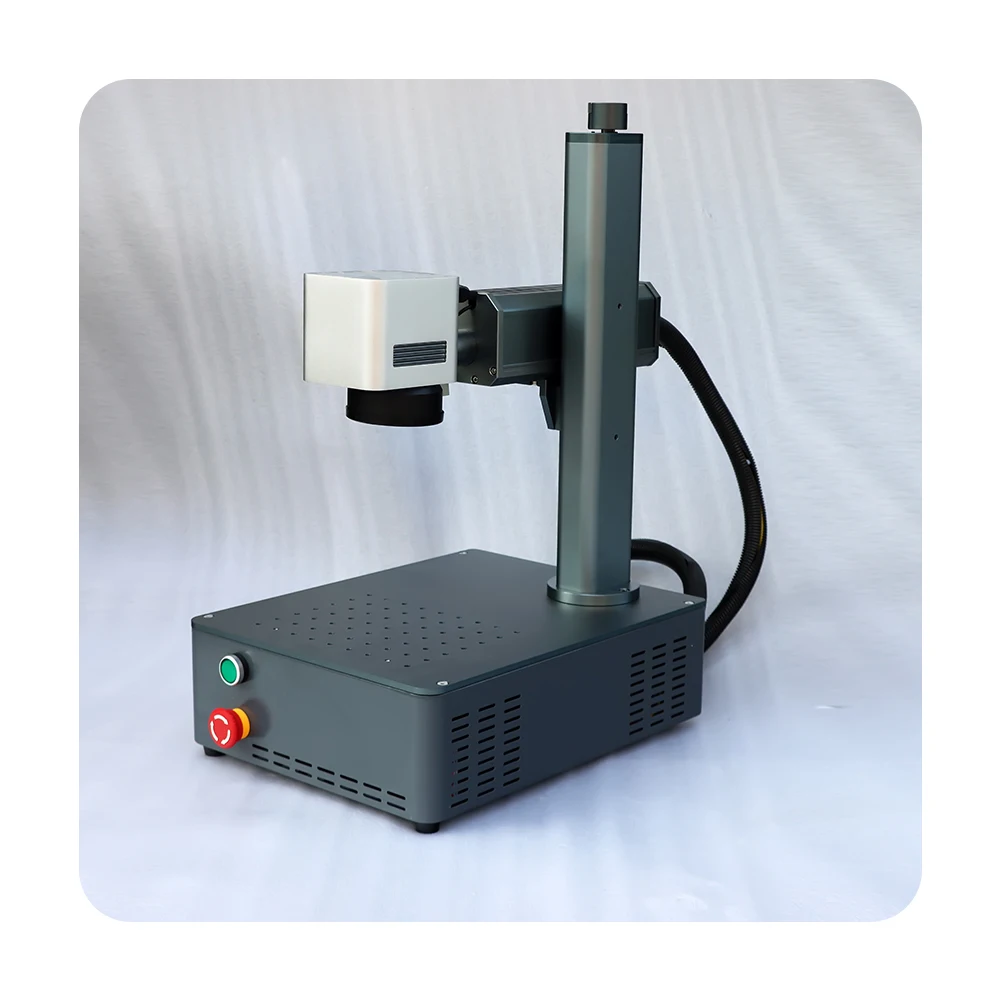

2. Rich intellectual property rights: By July 2024, the company currently holds 2 design patents (laser welding machine and laser marking machine), 1 trademark and 2 work copyrights. This indicates the company's innovation and protection ability in product design, brand and cultural creation.

3. The product application is wide: also the area of application of its laser marking machine is from metal, paper, plastic, beer bottle, packaging bag, dates, gift, handicrafts, food, textile, chemicals, toys, catering and daily chemical products, tobacco, alcohol, medical, hardware, machinery etc.